I?m not making the VOR

I tried to get everything done in time but custom making brackets (no time to order), IC piping and wiring took me too long.

Then the new electric fuel pump took a shit. Finally tested and installed the old one and it started right up. That?s the good news.

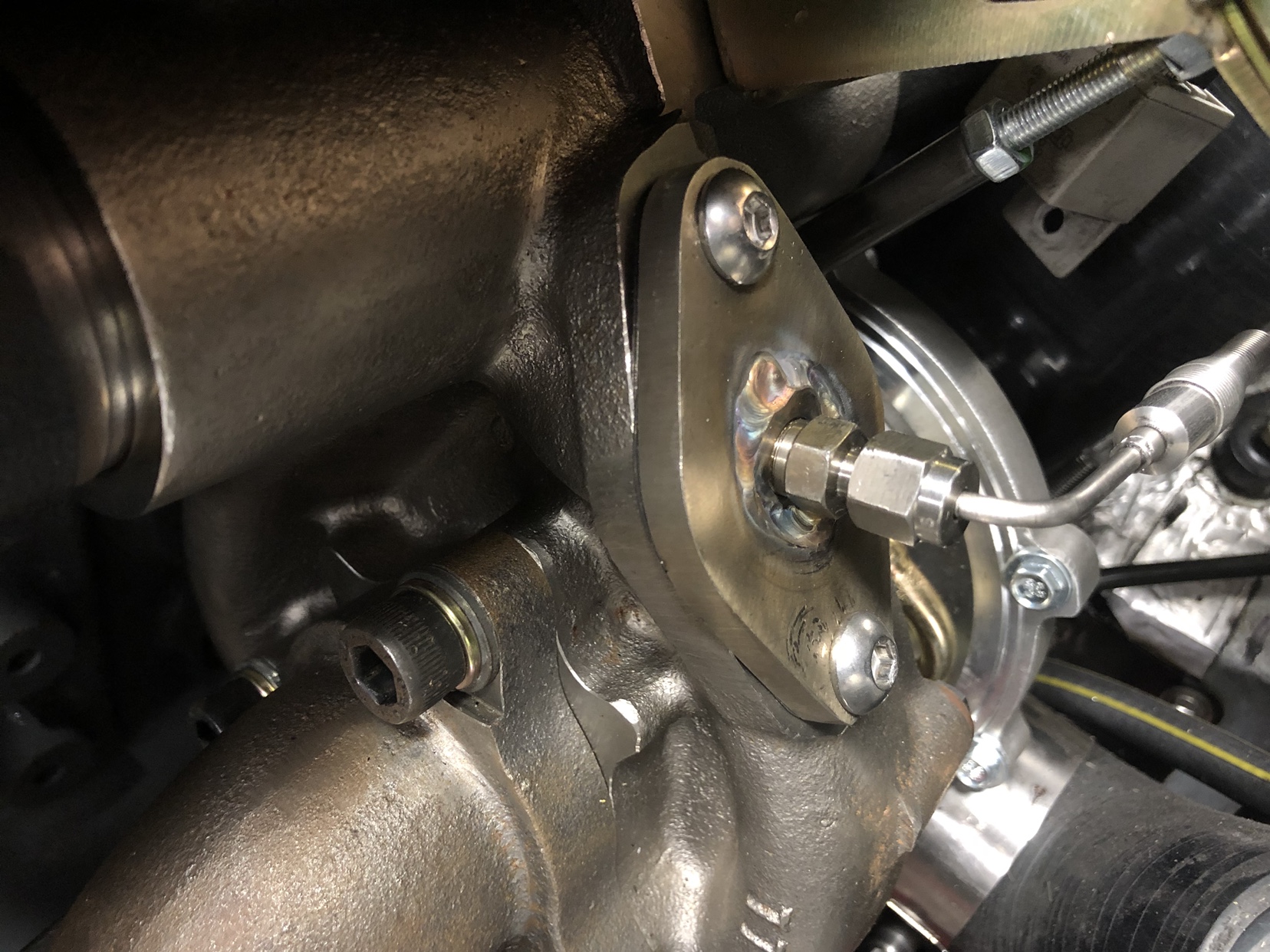

Added coolant and it?s leaking. I mistook 2 broken timing cover bolts as dowels. Engine on the stand I could have brought it to the torch and weld nuts on and pulled. It?s going to be harder now.

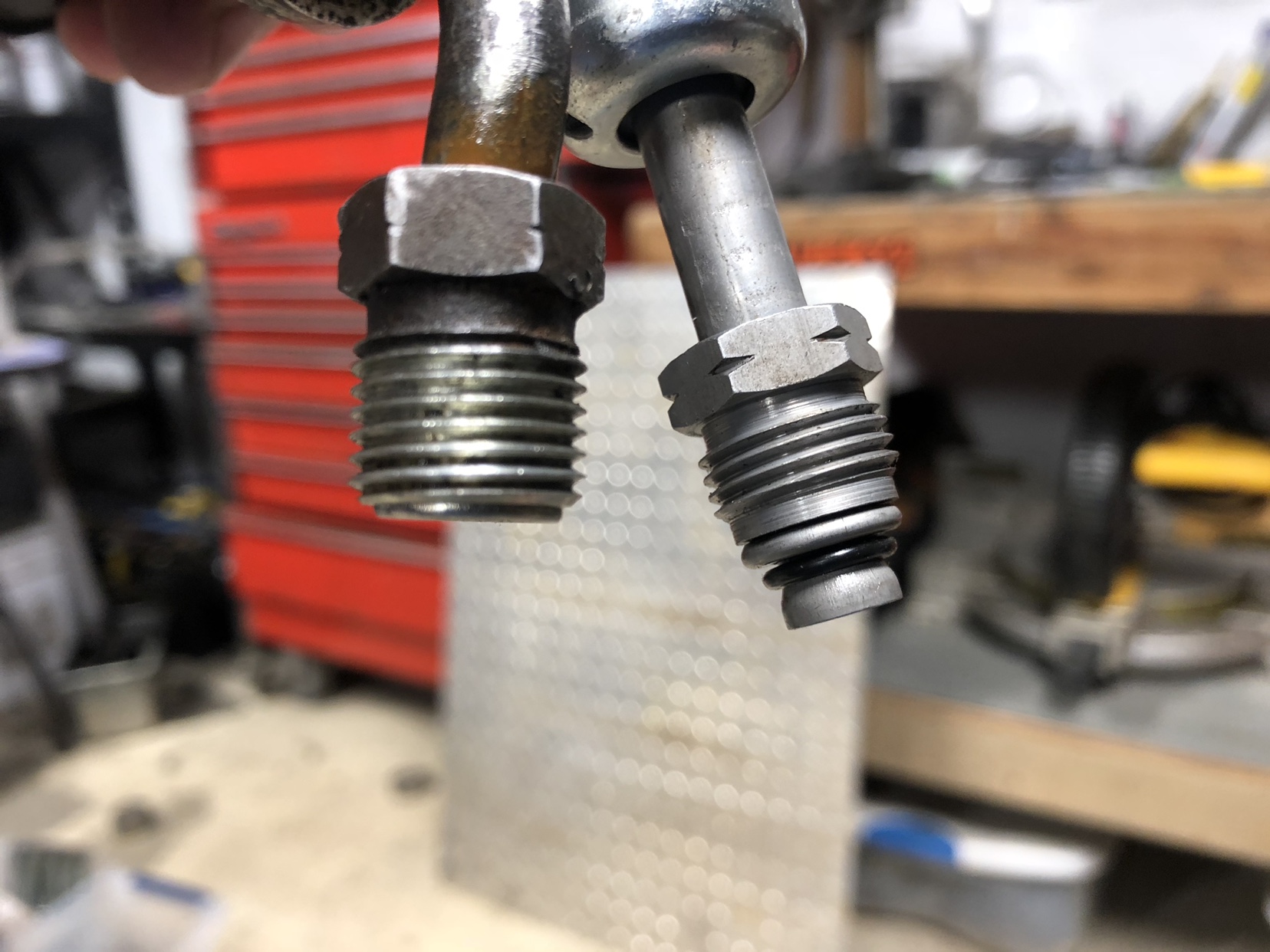

PS lines are messed up too. I ordered 3 different ones per the LR parts manual figuring at least one would fit. The PS pump on a 200tdi Discovery has different threads than anything. I grabbed some PS pipes and reservoir from my brother in laws RRC and that high pressure hose has the correct pump fitting but the configuration doesn?t fit.

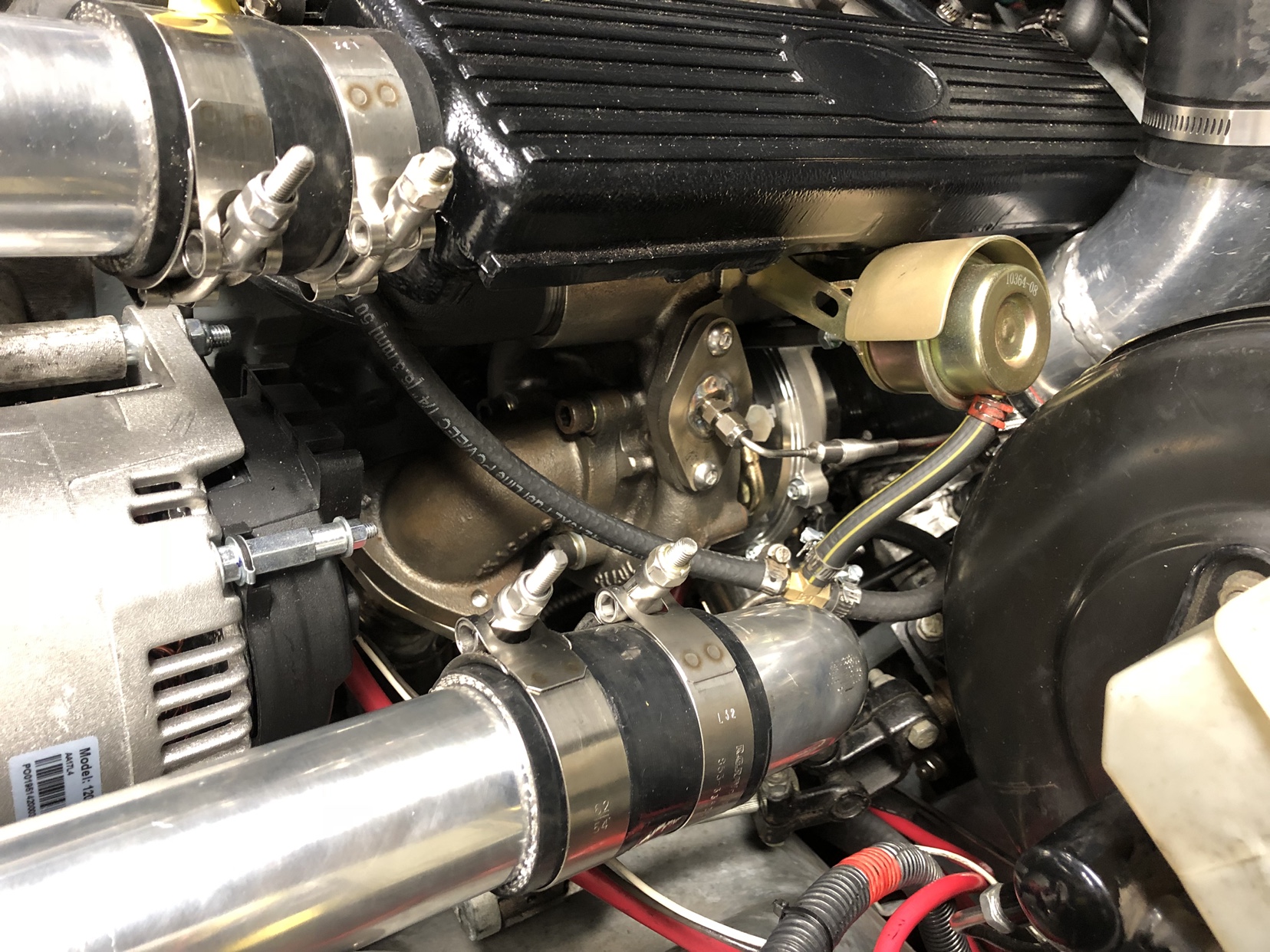

On the plus side I?m pretty happy with how the exhaust turned out. Clearance seems good and the pipe underneath is nice and straight. I might add another flex pipe like Napalm has on his.

The IC piping seems good for just a bunch of 2? stuff I ordered and pieces I had.

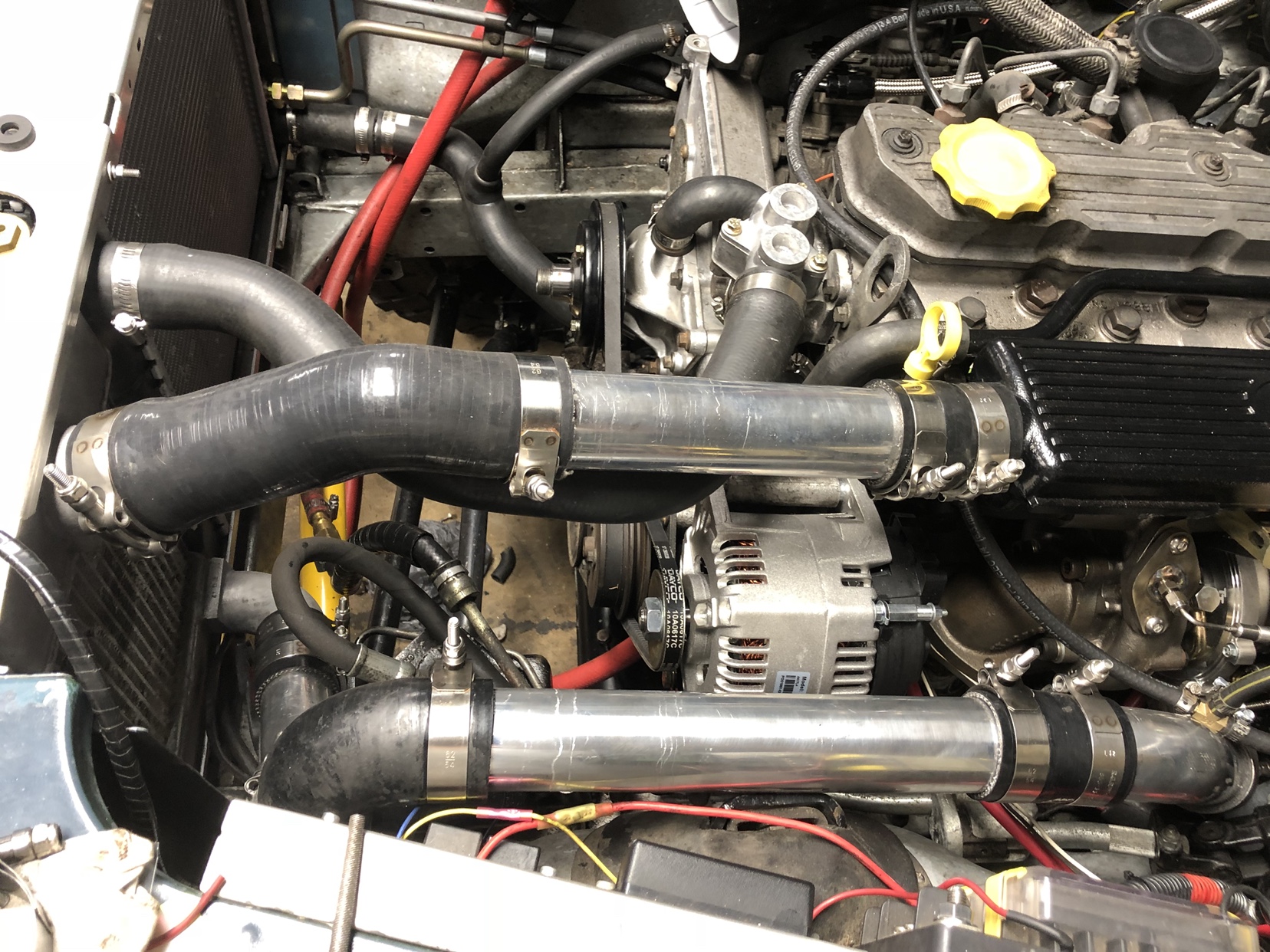

The radiator lines worked well too. I will take pictures and detail what I did to make it work.

Pic of the engine bay when I called it quits last night:

Sent from my iPhone using Tapatalk