donb

Well-known member

As some of you may know I'm currently have an OM617 in my 110 ST. It's been good but as of late the leaks have been killing me and I was on a search for more power via IP and bigger turbo. My main problem is I just want to drive the 110 and feel like the OM617 needs more work than I want to do right now.

At one point I was thinking a Cummins R2.8 but with no bolt-in setup available I didn't want to cut up my low use galvanized frame to make it work. And to be honest I'm tired of custom making parts to make things work.

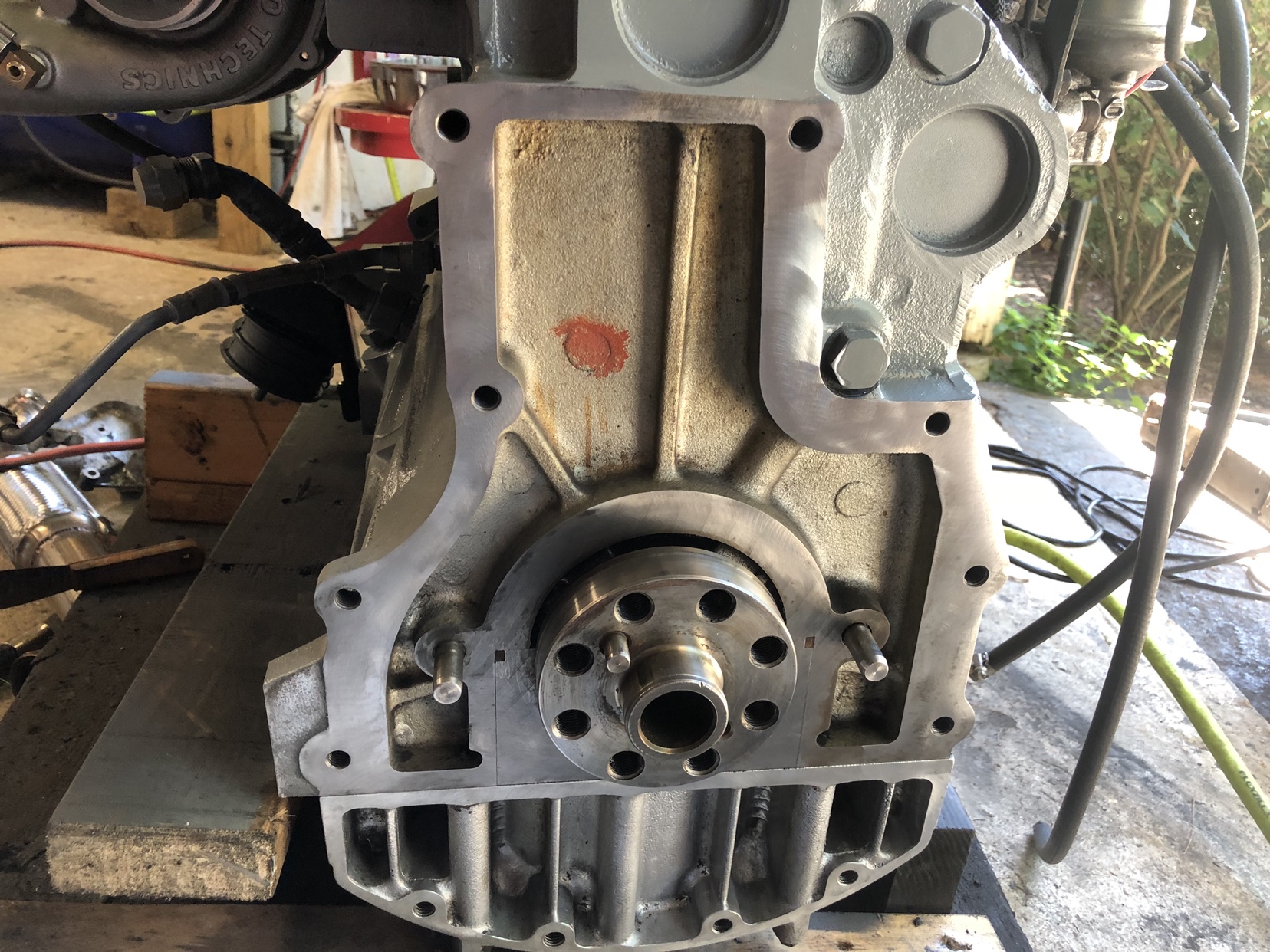

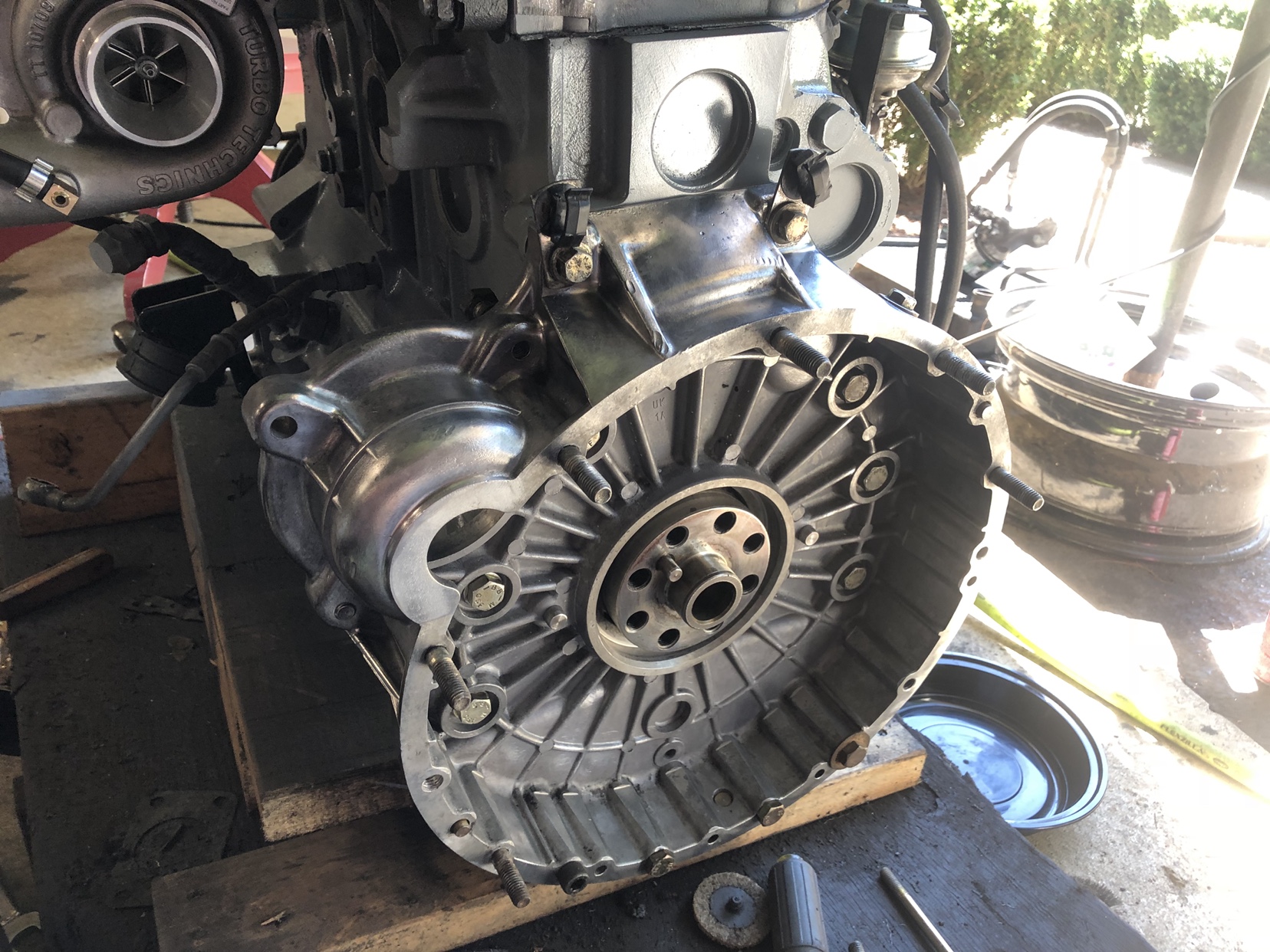

So I bought a Discovery 200tdi which as many know isn't a straight bolt in for a Defender anyway. But there is plenty of information out there for it. After receiving the engine I did a compression test with a kit from Harbor Freight. All cyclinders were over 400psi. After a couple fuel lines hooked up with an in-line filter I got it to run easily for a few seconds.

My prep plan is:

- Clean up

- install new rear main seal

- install Alisport 300tdi VVT turbo along with the 300tdi exhaust pieces and 300tdi intake

- change timing belt and pulleys

- new 130 clutch

- Glencoyne motor mounts

I have an R380 behind the Mercedes engine now. And a 200tdi radiator, intercooler and framework so I'm hoping things will be straight forward.

I'll be posting pics as I work on stuff to document it and hopefully help people out and ask for help as I hit certain issues.

At one point I was thinking a Cummins R2.8 but with no bolt-in setup available I didn't want to cut up my low use galvanized frame to make it work. And to be honest I'm tired of custom making parts to make things work.

So I bought a Discovery 200tdi which as many know isn't a straight bolt in for a Defender anyway. But there is plenty of information out there for it. After receiving the engine I did a compression test with a kit from Harbor Freight. All cyclinders were over 400psi. After a couple fuel lines hooked up with an in-line filter I got it to run easily for a few seconds.

My prep plan is:

- Clean up

- install new rear main seal

- install Alisport 300tdi VVT turbo along with the 300tdi exhaust pieces and 300tdi intake

- change timing belt and pulleys

- new 130 clutch

- Glencoyne motor mounts

I have an R380 behind the Mercedes engine now. And a 200tdi radiator, intercooler and framework so I'm hoping things will be straight forward.

I'll be posting pics as I work on stuff to document it and hopefully help people out and ask for help as I hit certain issues.