Ash

0

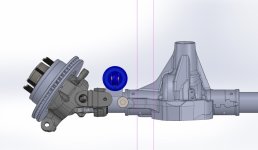

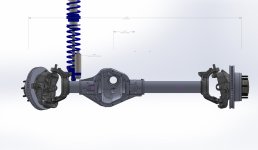

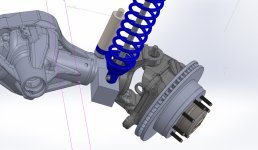

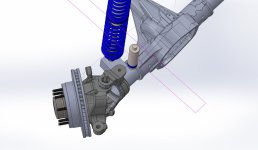

My plan is to do coil overs for packaging purposes, and I always thought the SG Stage IV D90 (Brendon Loveday's rig) was super cool, so I wanna go that direction... and #407's frame has taken a beating, so it's not like I'm violating a sacred clean NAS 90 frame. The frame needs some repairs.

Also, thanks for that pic, that does give me a frame of reference to work with.

I could give a shit about cutting up a NAS, that comment was solely in the context of time, complexity and expense. 10-12" of fully usable travel front and rear is attainable with coil springs, so unless you really need the tunability that coilovers offer, I do see them as unnecessary on a mid-travel build. To echo @Robert, sometimes less is more and you may reach a point where you wish you'd bitten off less, especially if you're building this with limited resources. Just something to consider. It'll be a cool build whatever the case, I'll be watching for sure.