Ben,

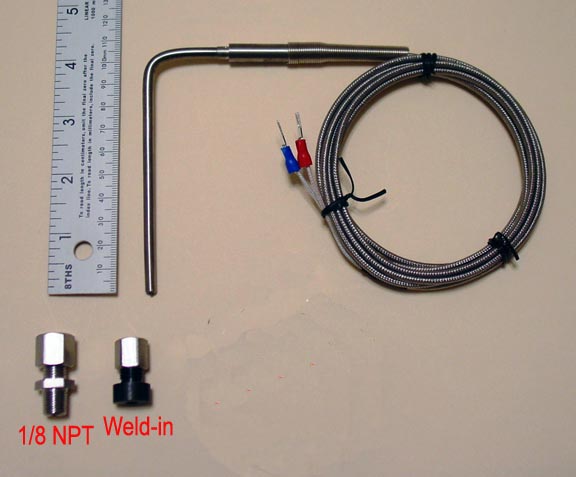

Your location is perfect but the probe may not be long enough. The tip needs to be mid stream. This is what I install in 300Tdi motors and is 100% compatible with VDO gauges.

https://www.auberins.com/index.php?main_page=product_info&cPath=5_22&products_id=145

How did you connect the wires to the gauge? I'm wondering how we know the gauge is telling us the right temp without any kind of baseline to calibrate from, and whether or not the wire length has anything to do with the readings. My wire has about 8 feet coiled up behind the dash.