donb

Well-known member

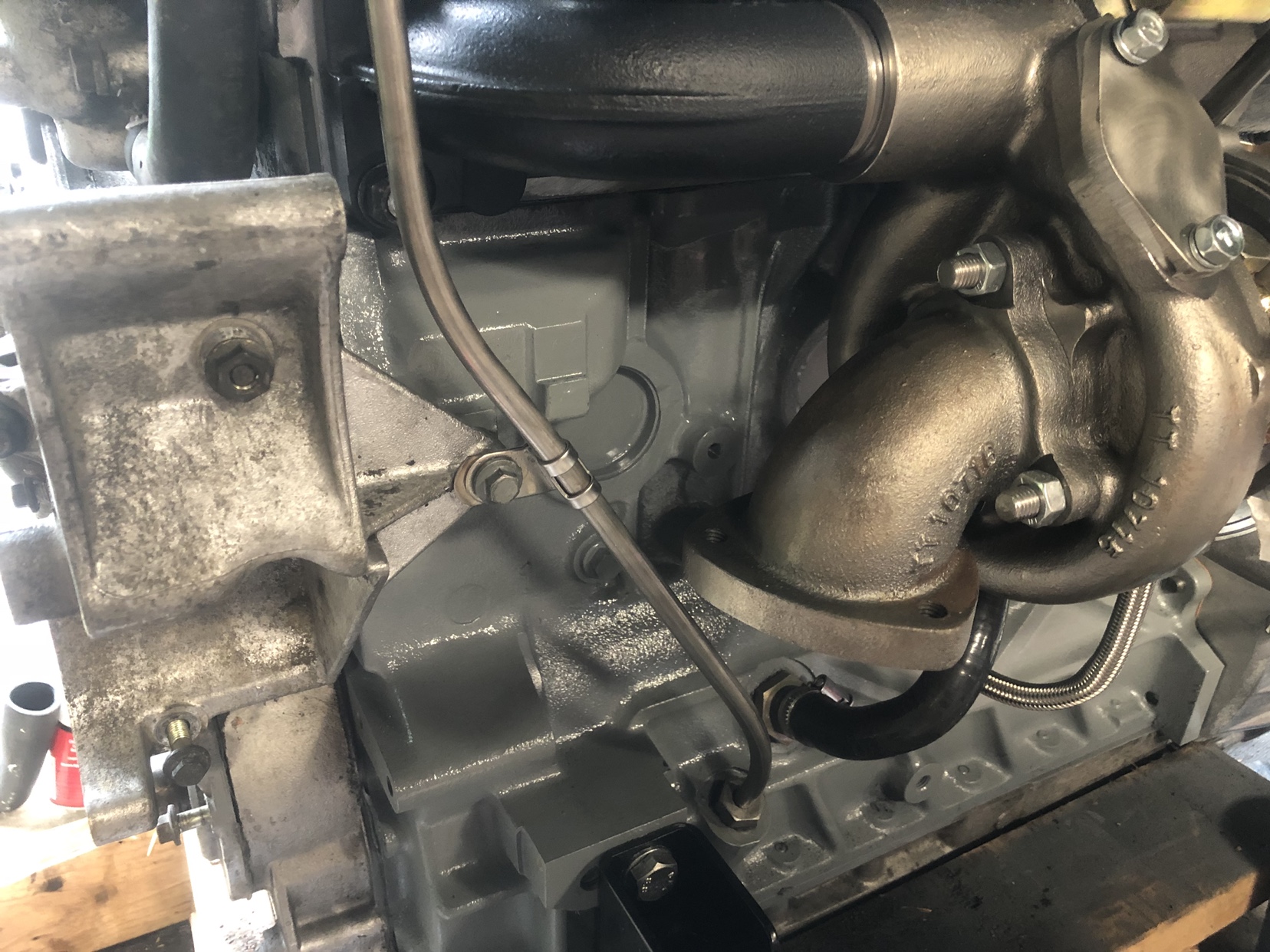

Finished up the turbo install.

I used a 300tdi manifold gasket which seemed to fit fine. I had to use longer M10 studs though.

The Alisport turbo kit includes a drain. I have a new 300tdi turbo oil feed on order.

Few pics of install. I had the 2 exhaust pieces ceramic coated. Overkill and a little expensive. Next time I?ll use the ceramic high heat spray paint I found at Lowe?s the other day.

I bought some 1/2? stainless bar at the metal yard the other day. Made an EGR plate and will get a bung to weld on for the EGT port.

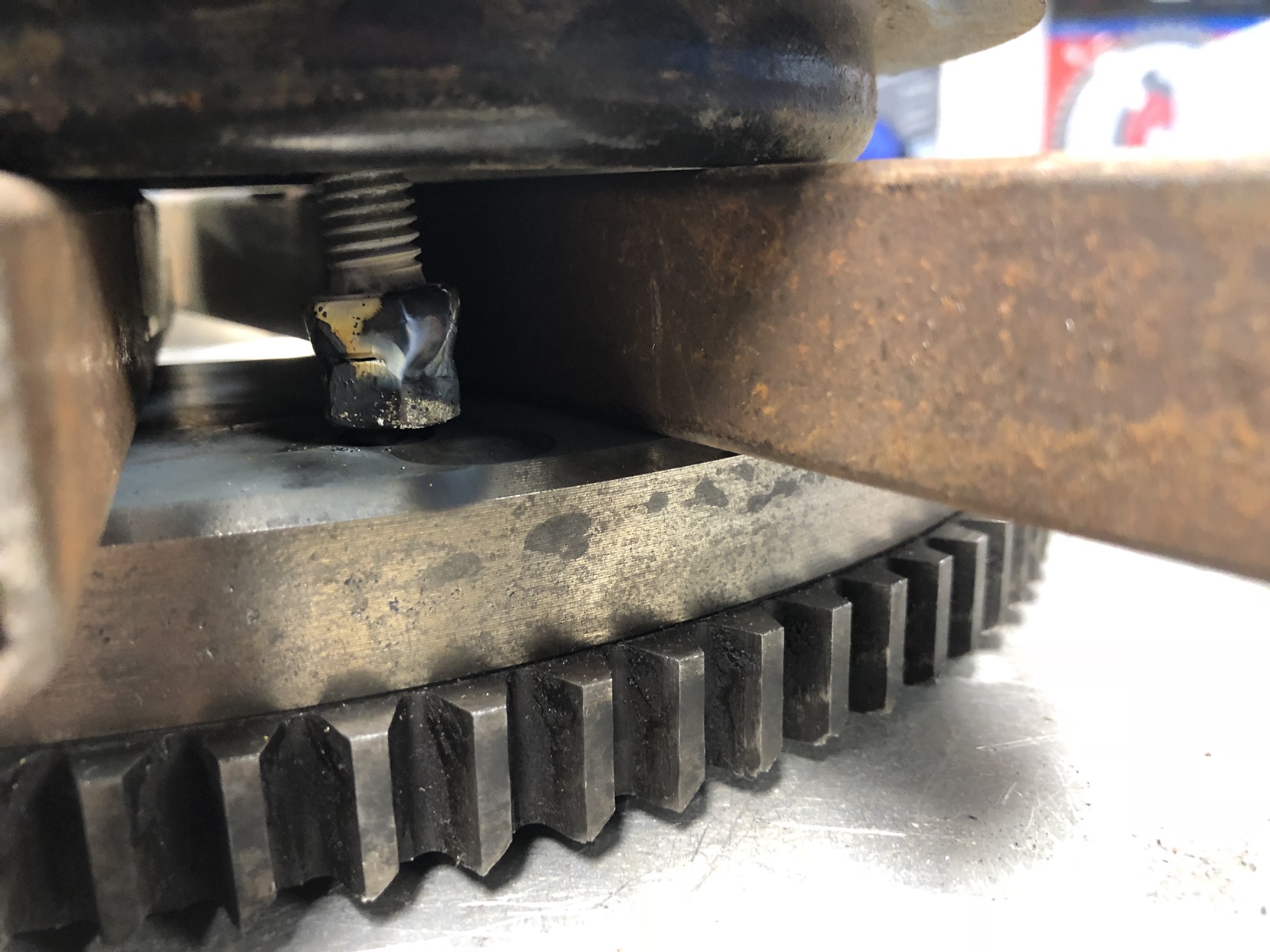

RH side engine mount with a Glencoyne bushing:

Sent from my iPhone using Tapatalk

I used a 300tdi manifold gasket which seemed to fit fine. I had to use longer M10 studs though.

The Alisport turbo kit includes a drain. I have a new 300tdi turbo oil feed on order.

Few pics of install. I had the 2 exhaust pieces ceramic coated. Overkill and a little expensive. Next time I?ll use the ceramic high heat spray paint I found at Lowe?s the other day.

I bought some 1/2? stainless bar at the metal yard the other day. Made an EGR plate and will get a bung to weld on for the EGT port.

RH side engine mount with a Glencoyne bushing:

Sent from my iPhone using Tapatalk