I wanted to take a moment to share my experience with Richard Crouch at Rover Resource (www.roverresource.com).

I purchased a 'refurbished' Defender 200tdi motor from Richard last year. The deal was it was not a 'full', 'new', rebuild but a refurb - take it down to bare block, hone cylinders, new gaskets, bearings - existing ancillaries etc. My interpretation was 'solid block, properly timed, shitty ancellaries'. I already had most of the ancillaries so was not concerned with them being 'old'. Richard sent me pictures of the block while being honed and later when it was painted. I paid and all was well ‘ the motor was delivered as expected and on time. It still needed a lot of cleaning up which I expected ‘ NBD.

Fast forward to early April 2018. After fitting all new hoses, ancillaries etc., and mating to a new Ashcroft stumpy R380, I dropped in the motor. Again, everything is as expected ‘ nothing to see here. The motor fired up without any hesitation ‘ I ran it for 30 seconds or so prior to filling with coolant. That same day I decided to fill with coolant and run it for a few to start tidying up and troubleshooting any issues. As I poured coolant into the radiator, coolant began to drip. Then drizzle. Then absolutely pour out of somewhere I could not tell. I quickly found that the coolant was pouring out of the water pump port > block. My immediate assumption is that there was not a gasket.

I called Richard and we discussed the situation. At the time I was stressed and definitely angry because I was in the final stages of buttoning up the motor and had a slew of other projects to complete before an upcoming trip. Richard assured me he would make it right. We discussed whether there was a shop nearby that could do the work (front cover, timing, etc.). I called Bill at Great Basin and he agreed they could do it but the turnaround timeline would be questionable. I decided to do the work myself. The first bolt I pulled was the top/right water pump bolt.

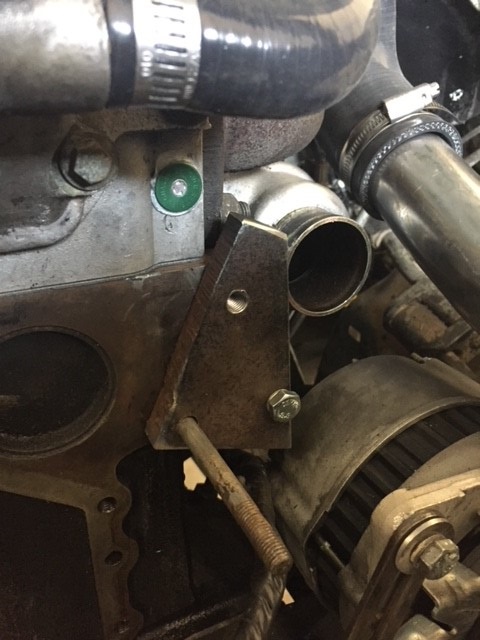

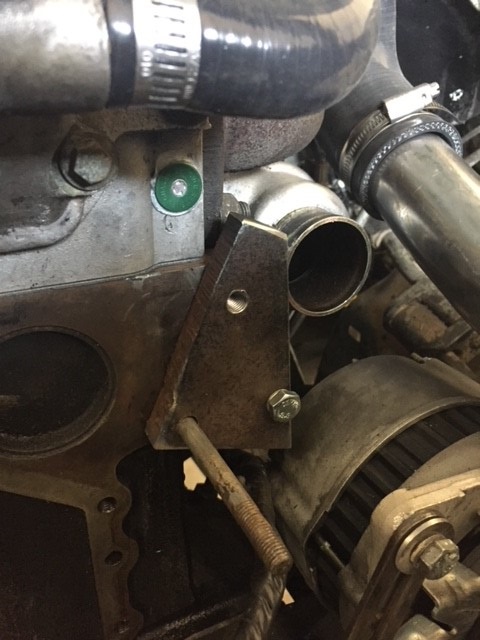

This is the moment I pulled that bolt.

A stripped bolt in the block is never good. This made me question the entire motor and the work performed (I’m still questioning it).

I broke down the front of the motor taking all the appropriate steps for timing. When I pulled the cover off ‘ this is what I saw.

This made me gasp. As suspected the .50 gasket was missing but that did not shock me. Anyone with any mechanical knowledge or experience would know that this oblong hole is not sound.

Richard and I discussed again ‘ my point to him was ‘ how could you possibly put a motor together and A) not notice this B) not care C) not think I would ever know/ notice. WTF’ I was pissed. He assured me he would make it right and pay to have it corrected. While reviewing the options of how to correct (do I have it towed to a machine shop, do I pull the motor and have another shipped out etc.) All of this while the hours ticked by closer to my trip date and I got more and more behind on everything else. Richard did some research and sent me a few machine shop numbers. In the meantime, I had built a tooling that would help me (or the machine shop) find the center of the hole. That was the biggest question. Like, adding a heli coil isn’t a big deal ‘ but, where is the center’ So, I made a 1/2in thick steel template using the water pump holes as a guide.

The bottom left hole would slide onto the ‘stud’, the bottom right would be bolted to the existing block hole, and the top hole would provide a guide to find ‘center’. At the last moment before I was going to start drilling, I decided to stop, take Richard up on the offer to have a machine shop attempt to fix.

I called several shops and settled on the very best vendor I’ve ever worked with ‘ WMC machining in West Valley City, Utah. I called at 9:00am on a Monday, and the shop TL, Craig Wyllie was at my house at 12:15 to review. Initially he was very apprehensive that the block could even be fixed. After thorough discussion, he agreed to take the job. He took the template I had made and would use it to make another ‘tooling’. The next day the machinist showed up and within ~40 minutes, the ‘keensert’ was in and good to go.

One note is that the machinist confirmed that, ‘there is a broken tap inside this hole’. Someone (Richard, PO’), had attempted to drill/ tap this hole and subsequently broke a tap inside.

I buttoned up the case/ front cover etc. The hole that WMC corrected was dead on center and the bolt went in without any issue.

Wrap-up:

Prior to the fix, Richard had agreed to ‘make this right’ and to ‘pay for the fix cost’. Also ‘once we get through this and the motor is running well, determine how many dinners I owe you’. I finished my truck and made the trip. The motor performed well through the 1500+ off road miles through Nevada, Utah, and Arizona. After the trip I sent Richard the invoice and asked for an additional $1200 reimbursement for my time to correct his error. He immediately reimbursed me for the machining and declined the additional $1200. He offered to ‘buy me dinner at my favorite restaurant’. I have not respond to him. Although this was a major fuck up by him and I would not trust him to touch another motor, I learned a lot. I hadn’t ever done the case/ timing etc. and I’m glad I have that knowledge now. Richard was good to work with but I question the quality of his work. Make your own judgement.

I purchased a 'refurbished' Defender 200tdi motor from Richard last year. The deal was it was not a 'full', 'new', rebuild but a refurb - take it down to bare block, hone cylinders, new gaskets, bearings - existing ancillaries etc. My interpretation was 'solid block, properly timed, shitty ancellaries'. I already had most of the ancillaries so was not concerned with them being 'old'. Richard sent me pictures of the block while being honed and later when it was painted. I paid and all was well ‘ the motor was delivered as expected and on time. It still needed a lot of cleaning up which I expected ‘ NBD.

Fast forward to early April 2018. After fitting all new hoses, ancillaries etc., and mating to a new Ashcroft stumpy R380, I dropped in the motor. Again, everything is as expected ‘ nothing to see here. The motor fired up without any hesitation ‘ I ran it for 30 seconds or so prior to filling with coolant. That same day I decided to fill with coolant and run it for a few to start tidying up and troubleshooting any issues. As I poured coolant into the radiator, coolant began to drip. Then drizzle. Then absolutely pour out of somewhere I could not tell. I quickly found that the coolant was pouring out of the water pump port > block. My immediate assumption is that there was not a gasket.

I called Richard and we discussed the situation. At the time I was stressed and definitely angry because I was in the final stages of buttoning up the motor and had a slew of other projects to complete before an upcoming trip. Richard assured me he would make it right. We discussed whether there was a shop nearby that could do the work (front cover, timing, etc.). I called Bill at Great Basin and he agreed they could do it but the turnaround timeline would be questionable. I decided to do the work myself. The first bolt I pulled was the top/right water pump bolt.

This is the moment I pulled that bolt.

A stripped bolt in the block is never good. This made me question the entire motor and the work performed (I’m still questioning it).

I broke down the front of the motor taking all the appropriate steps for timing. When I pulled the cover off ‘ this is what I saw.

This made me gasp. As suspected the .50 gasket was missing but that did not shock me. Anyone with any mechanical knowledge or experience would know that this oblong hole is not sound.

Richard and I discussed again ‘ my point to him was ‘ how could you possibly put a motor together and A) not notice this B) not care C) not think I would ever know/ notice. WTF’ I was pissed. He assured me he would make it right and pay to have it corrected. While reviewing the options of how to correct (do I have it towed to a machine shop, do I pull the motor and have another shipped out etc.) All of this while the hours ticked by closer to my trip date and I got more and more behind on everything else. Richard did some research and sent me a few machine shop numbers. In the meantime, I had built a tooling that would help me (or the machine shop) find the center of the hole. That was the biggest question. Like, adding a heli coil isn’t a big deal ‘ but, where is the center’ So, I made a 1/2in thick steel template using the water pump holes as a guide.

The bottom left hole would slide onto the ‘stud’, the bottom right would be bolted to the existing block hole, and the top hole would provide a guide to find ‘center’. At the last moment before I was going to start drilling, I decided to stop, take Richard up on the offer to have a machine shop attempt to fix.

I called several shops and settled on the very best vendor I’ve ever worked with ‘ WMC machining in West Valley City, Utah. I called at 9:00am on a Monday, and the shop TL, Craig Wyllie was at my house at 12:15 to review. Initially he was very apprehensive that the block could even be fixed. After thorough discussion, he agreed to take the job. He took the template I had made and would use it to make another ‘tooling’. The next day the machinist showed up and within ~40 minutes, the ‘keensert’ was in and good to go.

One note is that the machinist confirmed that, ‘there is a broken tap inside this hole’. Someone (Richard, PO’), had attempted to drill/ tap this hole and subsequently broke a tap inside.

I buttoned up the case/ front cover etc. The hole that WMC corrected was dead on center and the bolt went in without any issue.

Wrap-up:

Prior to the fix, Richard had agreed to ‘make this right’ and to ‘pay for the fix cost’. Also ‘once we get through this and the motor is running well, determine how many dinners I owe you’. I finished my truck and made the trip. The motor performed well through the 1500+ off road miles through Nevada, Utah, and Arizona. After the trip I sent Richard the invoice and asked for an additional $1200 reimbursement for my time to correct his error. He immediately reimbursed me for the machining and declined the additional $1200. He offered to ‘buy me dinner at my favorite restaurant’. I have not respond to him. Although this was a major fuck up by him and I would not trust him to touch another motor, I learned a lot. I hadn’t ever done the case/ timing etc. and I’m glad I have that knowledge now. Richard was good to work with but I question the quality of his work. Make your own judgement.