hillstrubl

Founding Member

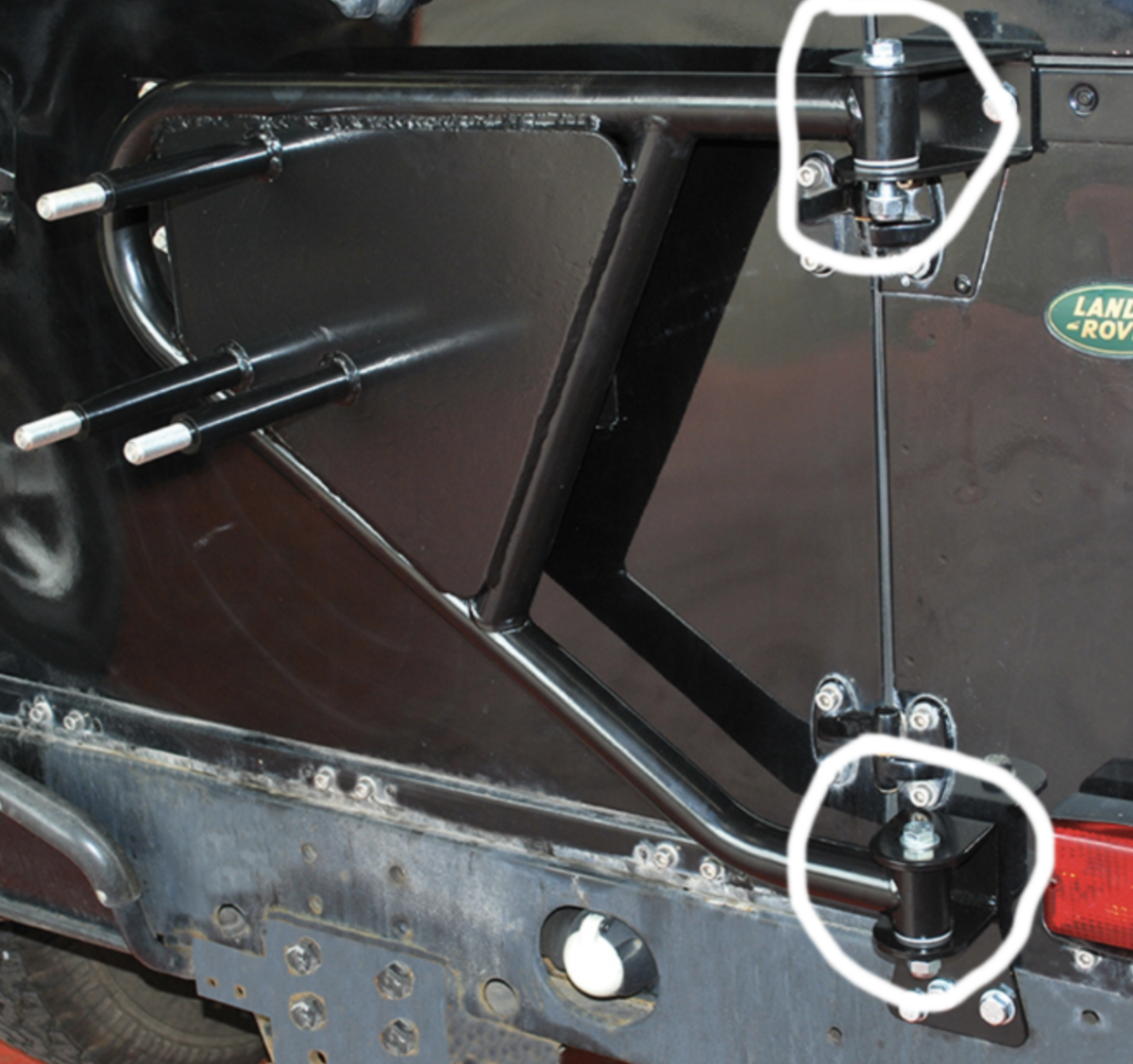

I've had the britpart knockoff of the mantec tire carrier for a few years now and something that always bothered me was a lack of grease fittings on the main load bearing hinges. I have some universal zerks that I could drill/tap and add, but then I thought, why not just replace the bolts with pre-drilled greasable ones.

The dimensions of the existing bolts (measuring in the dark with a standard tape measure...) are M18 head (but the nut on the bottom is a 19mm) x ~95mm (Measured as just shy of 1/2" diameter bolt shaft x 3.75" bolt length. This equates to me as M18 x 95mm. I guess it could be longer but I'm not sure I want another 25MM of threads sticking out from what's there now if I use something like this.

Anybody know a source of greasable bolts for an application like this? Already checked McMaster, Grainger and the River site.

The dimensions of the existing bolts (measuring in the dark with a standard tape measure...) are M18 head (but the nut on the bottom is a 19mm) x ~95mm (Measured as just shy of 1/2" diameter bolt shaft x 3.75" bolt length. This equates to me as M18 x 95mm. I guess it could be longer but I'm not sure I want another 25MM of threads sticking out from what's there now if I use something like this.

Anybody know a source of greasable bolts for an application like this? Already checked McMaster, Grainger and the River site.