The second step was to un-crate the R380 Stumpy and LT230 the owner had shipped to us from Ashcroft.

The stumpy has the heavy duty bearing modification, but does not have the higher 5th gear.

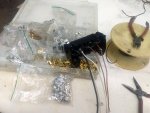

The third step was to make an assessment of the engine and note the ancillary parts.

The owner also supplied a new Delco 10Si alternator, and a new gear reduction starter.

The vehicle is being converted to power steering.

We noted 4 of the 5 factory power steering brackets were missing, but located some extra brackets on-line.

The 4th step was to install the flywheel, engine to transmission adapter, dust shield, and starter (which helps locate the dust-shield).

The GM flywheel was surfaced to the correct height and drilled for the Land Rover clutch, so it bolted right on.

The conversion kit does not come with a flywheel.

We can supply a flywheel ready to bolt on for owners that don't want to have their flywheel machined or are missing the flywheel.

The fifth step was to install the pilot bushing that comes with the kit, the 130 TDI clutch, and assemble the clutch release mechanism for the R380 stumpy.

The custom pilot bushing housing uses the factory Land Rover pilot bushing.

The stumpy has a unique clutch release bearing. The 300TDI release bearing that came with the heavy duty 130 clutch kit cannot be used.

.

.