MountainD

Technical Excellence Contributor

Yada yada yada...DISCLAIMER: this is what I do and brakes are SUPER important. So don't take this as a manual and if I have something wrong, then by all means let me know and I can amend this. But I have rebuilt several of my calipers over the years and this works for me. At your own risk. I'm an idiot and sometimes drink while I rebuilding. Meaning I am actually, physically drinking with one hand, scrubbing with the other.... If you are not comfortable working on brakes, then don't.

The brakes on my Sals when I got it were a bit rusty and frozen up solid. But brakes are simple and as long as they are not too far gone, rebuilding them is fairly easy. I prefer the Lockheed brakes over the aftermarket so I chose to rebuild them. First thing I did was clean them up--this happened last year and I didn't take photos as I think we all know how to clean up crap. Wire brush, elbow grease, maybe a sandblaster---whatever you do/use just make sure all the ports are plugged and leave the pistons in place at this point. It will protect the bores and isn't necessary. Once that is done, I always paint them. You have to use a brake caliper paint or something that is very high heat resistant and chemical resistant as brake fluid is rather nasty. So paint them. Couple coats. PISTONS STILL IN---don't worry--it still protects the bores.

OK, so let's start the rebuild. The first thing we need to do is get those pesky frozen pistons out of the bores. How I do it, even when frozen is the same. It is scary as it is loud as shit. Put a 2x4 between the pistons. That is step one. Now, you need the bore where the caliper hose goes so make sure that is clear and remove your plug. Make sure your bleed screw is in and tightened so you can use compressed air. With board between pistons, use your rubber tipped air compressor air gun and put air right into the caliper. This will free up one side of the pistons typically:

Next, I take a C-clamp and whichever side moved, I pin it back (but not all the way in, a little is protroduing so I can grab it)---this is so I can break the other side free. The 2x4 will no longer fit, so I shove a rag in there. That caliper is going to release with a BANG! when that caliper pops out so beware! I forgot to show the pic, so below you don't see the rag. I staged it.

Now you are free to break the two halves apart. Remove the two bolts. They are tight.

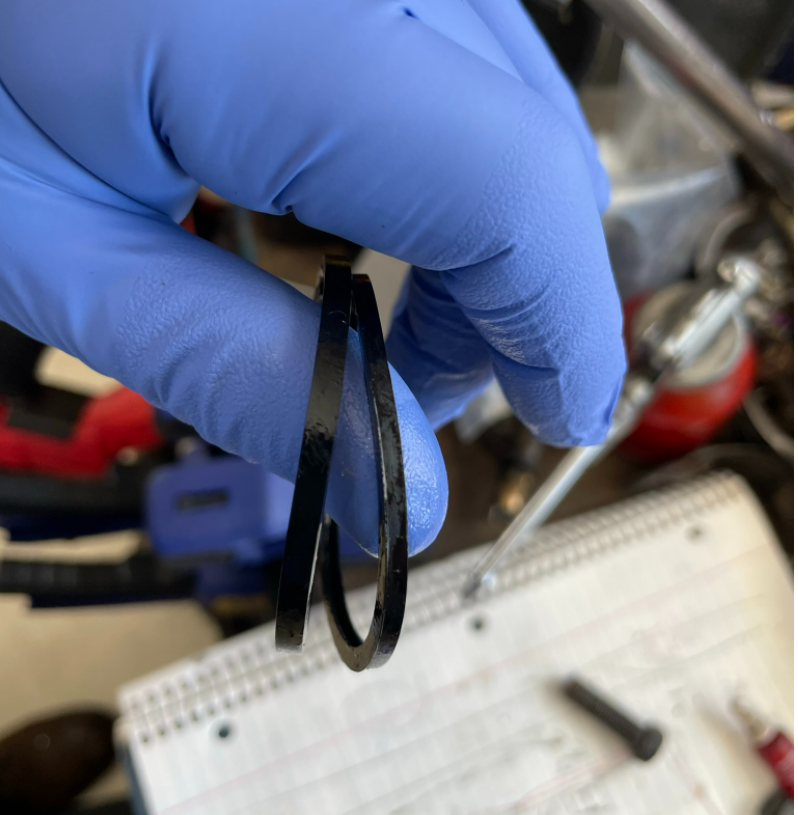

Throughout the entire process, I want you to concentrate on ONE thing! Safety? OK, two things. Don't hurt yourself or the dog. And DONT lose this square oring seal. I have found small ones for other calipers, but I can't seem to find this one so you are going to reuse it. Don't lose it. If someone has a source, great--Let us know! This is when I take out the bleed valves and blow out every hole and line of the halves. Being mindful NOT to lose the o-ring. If you do and can't find another one (or damage it), then game over.

With the halves apart you can use some channel locks and twist out the second piston if it is not already out. Then remove the seals with a small screwdriver. Pry them out being attentive to not hurt the bores. Mine came out stuck/painted to the pistons---one less thing to worry about. Clean out this channel as it is where one of the two seals you will replace go. Inspect your bores. I use a little scotchbright pad and do a once-over on the bores and then I fit the new pistons, lubricated with a little brake fluid, to make sure they are smooth and go all the way to the bottom such that they are flush with the top. This is necessary for my next step. Take them back out--just turn the caliper upside down and they should fall out with gravity if it is clean and smooth.

Here is a test fit to make sure it is smooth. Solid side goes down. If you put them in solid side up, then when you do the brakes, you need to fill up that entire center hollow part with fluid---they go in with the solid side down. What I am doing is making sure it was flush when fully seated.

Tech Tip: When you scotchbrite and work on the half that has the raised portions, I find it helpful to tape them up so they don't cut my hands. The edges are sharp.

There are TWO seals, a wide and a narrow. The wide one goes in the groove deeper in the recess--it goes in there alone.

The narrow one goes inside the metal ring.

The first time I did a rebuild, I F-ed up a lot of these until I found a better way that is fairly used now. Wish I knew it then as once I started doing it this way I never screwed up another seal---this is the BEST TIP I HAVE for rebuilding brakes. Ready for it? First, fit the ring and seal over the top of the piston. This is going to guide the entire thing and allow it not to buckle and it keeps its shape. VITAL. Note: The solid side of the piston (shown up in this photo) goes INTO the caliper first.

The brakes on my Sals when I got it were a bit rusty and frozen up solid. But brakes are simple and as long as they are not too far gone, rebuilding them is fairly easy. I prefer the Lockheed brakes over the aftermarket so I chose to rebuild them. First thing I did was clean them up--this happened last year and I didn't take photos as I think we all know how to clean up crap. Wire brush, elbow grease, maybe a sandblaster---whatever you do/use just make sure all the ports are plugged and leave the pistons in place at this point. It will protect the bores and isn't necessary. Once that is done, I always paint them. You have to use a brake caliper paint or something that is very high heat resistant and chemical resistant as brake fluid is rather nasty. So paint them. Couple coats. PISTONS STILL IN---don't worry--it still protects the bores.

OK, so let's start the rebuild. The first thing we need to do is get those pesky frozen pistons out of the bores. How I do it, even when frozen is the same. It is scary as it is loud as shit. Put a 2x4 between the pistons. That is step one. Now, you need the bore where the caliper hose goes so make sure that is clear and remove your plug. Make sure your bleed screw is in and tightened so you can use compressed air. With board between pistons, use your rubber tipped air compressor air gun and put air right into the caliper. This will free up one side of the pistons typically:

Next, I take a C-clamp and whichever side moved, I pin it back (but not all the way in, a little is protroduing so I can grab it)---this is so I can break the other side free. The 2x4 will no longer fit, so I shove a rag in there. That caliper is going to release with a BANG! when that caliper pops out so beware! I forgot to show the pic, so below you don't see the rag. I staged it.

Now you are free to break the two halves apart. Remove the two bolts. They are tight.

Throughout the entire process, I want you to concentrate on ONE thing! Safety? OK, two things. Don't hurt yourself or the dog. And DONT lose this square oring seal. I have found small ones for other calipers, but I can't seem to find this one so you are going to reuse it. Don't lose it. If someone has a source, great--Let us know! This is when I take out the bleed valves and blow out every hole and line of the halves. Being mindful NOT to lose the o-ring. If you do and can't find another one (or damage it), then game over.

With the halves apart you can use some channel locks and twist out the second piston if it is not already out. Then remove the seals with a small screwdriver. Pry them out being attentive to not hurt the bores. Mine came out stuck/painted to the pistons---one less thing to worry about. Clean out this channel as it is where one of the two seals you will replace go. Inspect your bores. I use a little scotchbright pad and do a once-over on the bores and then I fit the new pistons, lubricated with a little brake fluid, to make sure they are smooth and go all the way to the bottom such that they are flush with the top. This is necessary for my next step. Take them back out--just turn the caliper upside down and they should fall out with gravity if it is clean and smooth.

Here is a test fit to make sure it is smooth. Solid side goes down. If you put them in solid side up, then when you do the brakes, you need to fill up that entire center hollow part with fluid---they go in with the solid side down. What I am doing is making sure it was flush when fully seated.

Tech Tip: When you scotchbrite and work on the half that has the raised portions, I find it helpful to tape them up so they don't cut my hands. The edges are sharp.

There are TWO seals, a wide and a narrow. The wide one goes in the groove deeper in the recess--it goes in there alone.

The narrow one goes inside the metal ring.

The first time I did a rebuild, I F-ed up a lot of these until I found a better way that is fairly used now. Wish I knew it then as once I started doing it this way I never screwed up another seal---this is the BEST TIP I HAVE for rebuilding brakes. Ready for it? First, fit the ring and seal over the top of the piston. This is going to guide the entire thing and allow it not to buckle and it keeps its shape. VITAL. Note: The solid side of the piston (shown up in this photo) goes INTO the caliper first.

Last edited: