For sure brother. Too bad the egr setup has to stay to keep it legal. I wonder if the water pump can be at fault as well.yep. as Chris noted...this is a common occurrence with the R2.8 (not just Defender installs).

If i recall correctly - engine throws an error code at 225degrees (which I consider on the low side compared to my car getting to 280's w/o a problem). Also noted previously...this doesn't happen on flat land or low elevation or without load on the engine. The issues to crop up during summer time heat (ambient near 100F), sustained uphill (load on the engine), or towing (again load on the engine) and all that at 5000ft+ elevation.

I believe that the purpose of posting here is to share the learned knowledge and hopefully save others from additional spend / time for cooling package installs. If your install is space limited and requires an eFan - I get it - again hopefully saving others time & money by making informed decisions.

From my own experience - I would say its the heat soak and the EGR cooler adding additional heat to the system.

My cooling package efforts:

v1.0 was a single pass radiator (372 sq in surface) w/ 1600cfm 16" SPAL. (this was behind a FMIC also 272 sq in)

v1.5 was upgrade to a 2000CFM SPAL (front area fully sealed so all air was directed through radiator)

v1.6 changing to a 50% smaller FMIC so that the radiator had clean air passing through it

v2.0 was upgrade to dual pass radiator that was 522 sq in (40% bigger core) - this dropped temps, but still higher than I want to see. (2000cfm SPAL/original shroud)(original shroud left some un-shrouded area to facilitate highway speed free flow) smaller FMIC also ducted to "hot side" of dual pass radiator, leaving "cool side" clear

v2.5 was change to Mechanical Fan - When I first installed mFan - eFan and shroud were still in place - temps dropped to acceptable level

v2.6 - removed eFAN & shroud, running mFAN un-shrouded for testing -- while I build a new shroud - no problems with cooling

v2.7 - *coming soon* - in the process of building the custom fiberglass shroud to facilitate proper flow through radiator.

Why the mechanical fan makes such a tremendous improvement over the E-fan can be many factors - I also struggled to understand how an eFan was not up to par with mFan.

1. static pressure in the engine compartment - hood vents could possibly fix this (I didnt go this route)

2. Fan blades - w/o getting into blade pitch, rpm, etc...mFan blades have more surface area

2. M-Fan does push more air (even prior to full clutch lockup) than the eFan (this could also be clearing out hot air from engine compartment

3. Currently with 60-70 degree ambient temps, murphy gauge stays in low 170's, with only partial flow from thermostat to radiator. Where I would hit 212 consistently w/ eFan, now only gets to 189MAX. Like Chris...I will likely be running a radiator muff into the winter so that proper warm up happens

If anyone is interested, I do have some used FMIC's, radiator, silicon hoses and fittings...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1991 200TDI to R2.8--couple remaining questions

- Thread starter MountainD

- Start date

MountainD

Technical Excellence Contributor

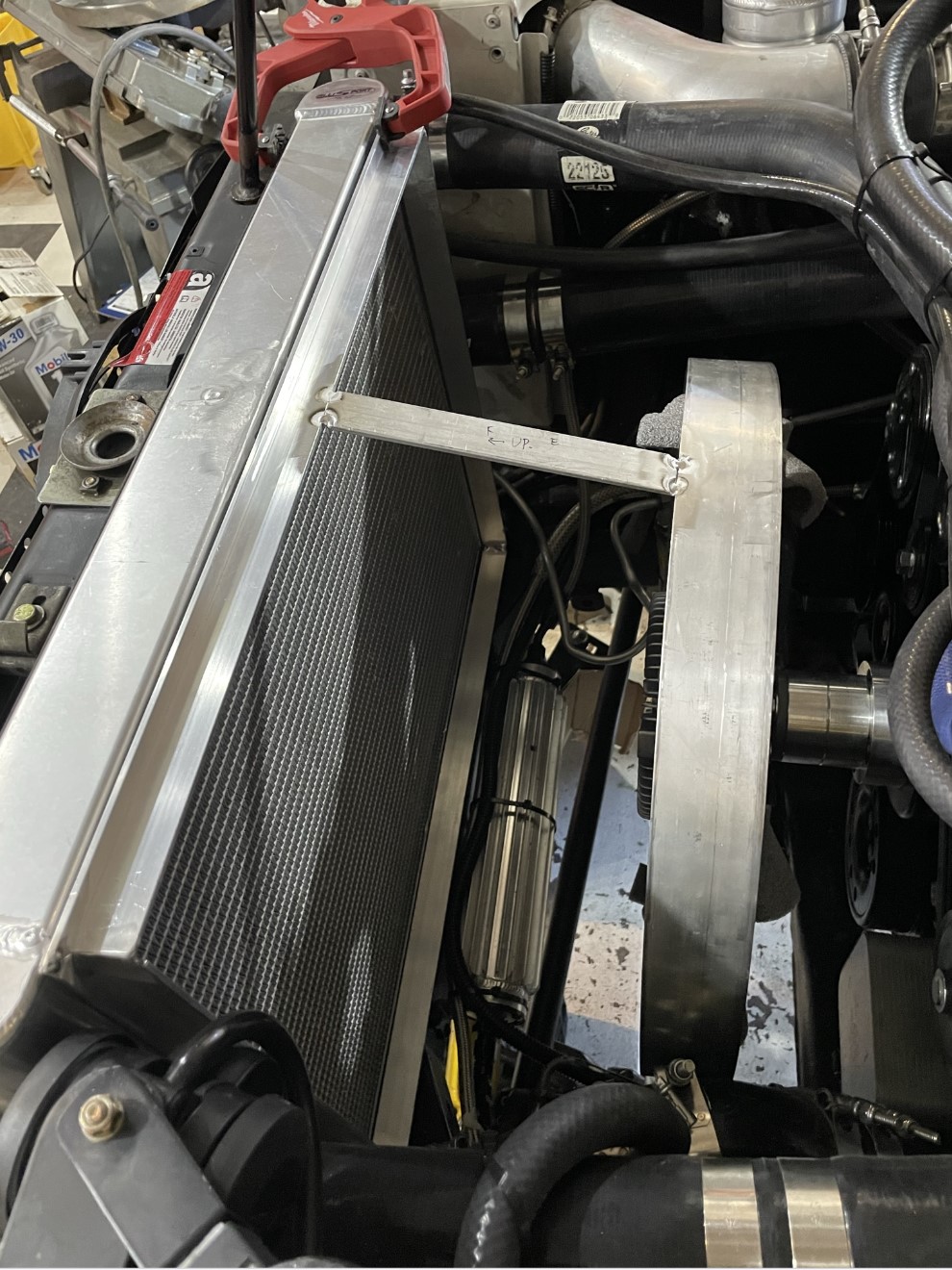

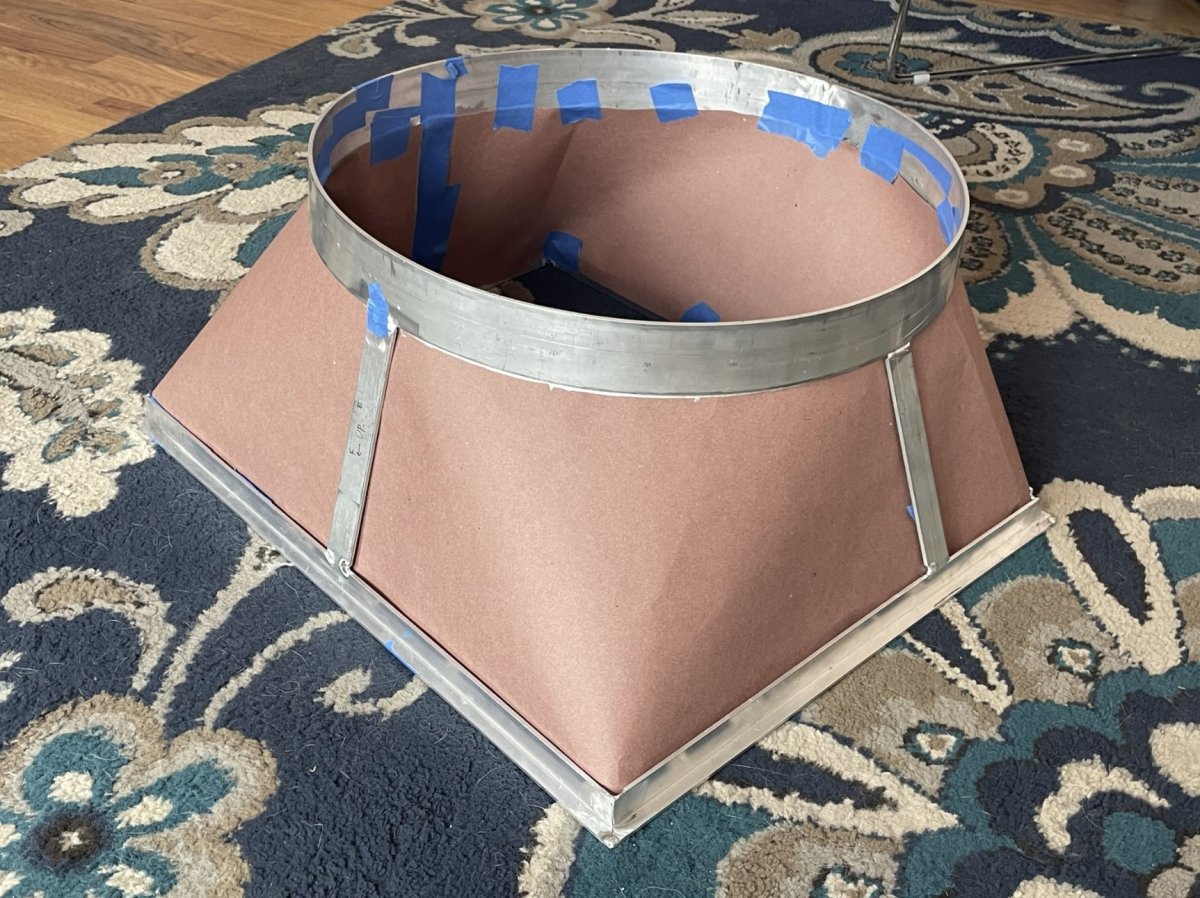

Work has really been "comprehensive" is the best way I can think to say--- so over winter I didn't drive too much and when I did it was quite cold so not heat issues. But I was figuring stuff out. I decided, as I mentioned, to convert to a mechanical fan and that has been a journey. I thought of doing it out of fiberglass but was concerned with weight and PITA so opted for aluminum...which I don't really work with. So I bought a TIG set up, learned to weld thin ass aluminum over the winter (just good enough, for now), and made a custom shroud. I rolled a frame for the fan side, welded a frame for the radiator side, then made some connecting supports between the two and then skinned the full thing with 0.040" thin aluminum. Thought (other than the welds) that it came out great, but truth is, it is just the first iteration to get the truck on the road for summer and way down the line I will remake it all nice and pretty.

First I rolled a hoop and cut it on the metal chop and welded it up.

To make it fit centered, I used pipe insulation on the fan blades that spaced the hoop about 3/4" from all sides of the fan:

I welded the radiator side frame and then tacked support struts on the sides to keep the assembly in place.

Then I used construction paper to make the general templates for the 1mm aluminum skin.

I skinned it and welded it up. I probably should have just run small 1" tacks, but I used it for practice and did a full weld up.

The welds are mediocre. But welding 0.040" aluminum (1mm) to a 0.125" frame is quite tricky. Only burnt through a couple times, nice penetration and the shroud is stout. 5.6lbs all in. Then painted matte black

Installed.

Recap---it works great. It was 72F yesterday, took it at 75mph and never got hot, just warm. Stayed at 180 at that speed. I will take it to the hills with the trailer to get the real world result and will follow up. So far, excellent cooling and super stoked.

When I remake it (since this is the first thing I see when I open the bonnet and want the welds beautiful) I will do it in two parts so the top half has a removable skin portion to aid in removing the fan. Just a little thing, but I want to do that. Maybe in a couple years. Maybe never. However, out of this process, I can now TIG aluminum

First I rolled a hoop and cut it on the metal chop and welded it up.

To make it fit centered, I used pipe insulation on the fan blades that spaced the hoop about 3/4" from all sides of the fan:

I welded the radiator side frame and then tacked support struts on the sides to keep the assembly in place.

Then I used construction paper to make the general templates for the 1mm aluminum skin.

I skinned it and welded it up. I probably should have just run small 1" tacks, but I used it for practice and did a full weld up.

The welds are mediocre. But welding 0.040" aluminum (1mm) to a 0.125" frame is quite tricky. Only burnt through a couple times, nice penetration and the shroud is stout. 5.6lbs all in. Then painted matte black

Installed.

Recap---it works great. It was 72F yesterday, took it at 75mph and never got hot, just warm. Stayed at 180 at that speed. I will take it to the hills with the trailer to get the real world result and will follow up. So far, excellent cooling and super stoked.

When I remake it (since this is the first thing I see when I open the bonnet and want the welds beautiful) I will do it in two parts so the top half has a removable skin portion to aid in removing the fan. Just a little thing, but I want to do that. Maybe in a couple years. Maybe never. However, out of this process, I can now TIG aluminum

MountainD

Technical Excellence Contributor

Started my last major mod, not engine related, but probably last mod for this thread. It’s my long waited rear seat conversion to the Disco2 black leather seat I got last year (took forever to find one in black).

I welded two 3/16” aluminum angle irons top and bottom) back to back to form the mounting tab, full length, for front mounts, and mounted with vertical and horizontal bolts through tub:

This moves seat forward a few inches enough so it doesn’t hit cubby, but allows as much load space as I could. I had to slice about 4” out of each side of tub making 8” wider for width (photo shows 3”, but wanted a little wider as it was tight), and seats fit great:

Now to tie in front tabs into mount and to make tub patches…

I welded two 3/16” aluminum angle irons top and bottom) back to back to form the mounting tab, full length, for front mounts, and mounted with vertical and horizontal bolts through tub:

This moves seat forward a few inches enough so it doesn’t hit cubby, but allows as much load space as I could. I had to slice about 4” out of each side of tub making 8” wider for width (photo shows 3”, but wanted a little wider as it was tight), and seats fit great:

Now to tie in front tabs into mount and to make tub patches…

MountainD

Technical Excellence Contributor

I welded a couple sides into the tub and out of position welding is HARD! Laying on my side trying to manipulate torch head, filler rod and squeeze / regulate pedal between my knees…damn. Welds started getting worse and worse, ruining all my work, then goddarn awful. Even though my tank read 0, I could clearly hear gas and my nozzle cone meter read 15cfh, the end-of-tank gas killed me. Picked up another 125cf tank and all is well…except a ton of repairs now necessary…. Guess I’ll be a grinder not a welder this weekend, lol.

once I got to this stage I knew what must be up…

But the gas gave out gradually. I will be able to spot it way earlier in the future. Always learning…

But the gas gave out gradually. I will be able to spot it way earlier in the future. Always learning…

once I got to this stage I knew what must be up…

MountainD

Technical Excellence Contributor

And the big mod crap is done! Today I finished welding and smoothing the rear cut outs and mounting the hold downs. If friggin pleased with how it came together and turned out. I have a little more work to button it up and finish the interior, but feeling great with what’s done!!!

dkemm

Well-known member

Back seat luxury!! Aka Date MobileAnd the big mod crap is done! Today I finished welding and smoothing the rear cut outs and mounting the hold downs. If friggin pleased with how it came together and turned out. I have a little more work to button it up and finish the interior, but feeling great with what’s done!!!

View attachment 27382

View attachment 27383

View attachment 27384

View attachment 27385

View attachment 27386

donb

0

The Disco 2 seat conversion came out awesome! Very tidy and it looks like some decent leg room with them as well.

And welding aluminum is very tricky - the material and it's thickness, the cleanliness, and weld settings all make a massive difference (at least for me). Both aluminum jobs came out really good especially the design aspects!

And welding aluminum is very tricky - the material and it's thickness, the cleanliness, and weld settings all make a massive difference (at least for me). Both aluminum jobs came out really good especially the design aspects!

MountainD

Technical Excellence Contributor

Thanks so much! I got to learn new skills and enlarge by horizons — feels really nice. Buttoned up the back minus below window trims. Thinking hard about back speaker panel and putting together game plan before tackling that part. Might get one of Scott’s. Back cargo is getting the. Vertical sides cover cover bottom seam at tube, and wheel arch pad overlaps sides. Then secured top to sides with a simple method of 3 finish nails through tops into the edge of the vertical. Works great, nothing slips around. Might reduce to a thinner pad in future as these are a little thick (3/4”) and heavy (94lbs for 4’x6’). But fine for now.

Still debating on cargo management.

Still debating on cargo management.

Last edited:

KW1985def110

Well-known member

forgive me if I missed it, but what diameter mechanical fan do you go with?

MountainD

Technical Excellence Contributor

https://www.amazon.com/gp/product/B004XOO0AK/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1. I went with 17” Derale reverse direction fan. And it’s been night and day between electric and mechanical. This is commuting to Denver, 30 miles in 80F weather, then hitting stop and go. 0 issues.

I’m designing a louvered radiator gril that has rotatable grill blades that can rotate and shut to restrict/heat the coolant more in winter Without me having to put my radiator muff on. I NEVER removed, drained or changed my coolant or system between transformation from electric to mechanical fans, and all my issues are gone.

I couldn’t go bigger than 17” due to proximity to power steering and coolant hoses. YMMV. Dont feel I needed bigger and I‘m borderline too much!. I’ll pull the trailer up a pass this coming weekend to fully tax system but without trailer, 100% good.

Having it complete has allowed me to move on and not look back…. Cranked out back seat, just installed a gull wing rear window, finishing up some trim work…. And very soon….CAMPING!

I’m designing a louvered radiator gril that has rotatable grill blades that can rotate and shut to restrict/heat the coolant more in winter Without me having to put my radiator muff on. I NEVER removed, drained or changed my coolant or system between transformation from electric to mechanical fans, and all my issues are gone.

I couldn’t go bigger than 17” due to proximity to power steering and coolant hoses. YMMV. Dont feel I needed bigger and I‘m borderline too much!. I’ll pull the trailer up a pass this coming weekend to fully tax system but without trailer, 100% good.

Having it complete has allowed me to move on and not look back…. Cranked out back seat, just installed a gull wing rear window, finishing up some trim work…. And very soon….CAMPING!

Last edited:

Thanks for sharing your cooling issues. I finally got my R2.8 installed and running and drove to Flagstaff for Overland Expo on its maden voyage. Going up long steady grades in 100 deg heat I faulted 3 times hitting 225 deg. Currently running elec 2 Spal fans from a Alisport (i think) setup with small shroud. Clearly I have a flow issue as well. Fans are F27P-12E8102.41S which at max pull 1170cfm, clearly not enough. Running Kraigs Intercooler/radiator combo which I though looked a little thin when installed. My steering box is even bigger than standard Defender (I have a Santana) and so I dont think I can run a mech fan but will measure again as I have tons of space between front of engine and radiator. I have found Derale dual elec fans that combined should pull close to 4000cfm.

Coming home, I drove by temp and let off on the steep/long grades and never faulted but temps would creep up to 220 and I would let off. Wasnt' running AC. I charged it but then everything leaked out night before the trip when truck cooled down. Must have a loose fitting. I havent driven her much since but planing in her as a daily soon. Around town, no issues. I really think it is purely a flow issue. I have AC condenser and front mounted IC and then radiator.

On the range rover classics, some friend have cut louvers in the hood to lower temps which helped quite a bit, but those engine bays are more sealed then mine.

Coming home, I drove by temp and let off on the steep/long grades and never faulted but temps would creep up to 220 and I would let off. Wasnt' running AC. I charged it but then everything leaked out night before the trip when truck cooled down. Must have a loose fitting. I havent driven her much since but planing in her as a daily soon. Around town, no issues. I really think it is purely a flow issue. I have AC condenser and front mounted IC and then radiator.

On the range rover classics, some friend have cut louvers in the hood to lower temps which helped quite a bit, but those engine bays are more sealed then mine.

MountainD

Technical Excellence Contributor

I have vents on the hood of my 90 running the LS and I don't feel it did enough—may have helped but didn’t solve anything when towing. I just got back from camping with mech fan on R2.8 pulling a 2000lb trailer over some of the steepest hills there are in CO, going 50mph (windy road) at 8500'. I had no issue, with or without AC. Matter of fact, I just opened the thermostat and the Murphy gauge red 193F for a brief moment. I usually run 175-180F. I am SOOOO happy I did the mechanical fan.

I would suggest you modify to the RRC steering box, outside of the frame rail, and run a mechanical fan/shroud if you want to be hot-weather, hilly, secure to the point you stop eyeballing your temp gauge. I went through 2 radiators, 2 intercoolers, 4 electric fan combos and never got stable enough to tow my trailer over passes. Now I can go all day, even at 75mph.

If you want advice on the Electric options, I am not your guy. Sorry. I don't believe in them with this motor. I didn't even drain my system when I swapped to the mechanical and all my issues went away.

Now only thing I struggle with is towing from a stop up a steep hill and getting the turbo up to speed to generate some torque without rev'ing a burning the clutch to hell (I am a manual....).

I would suggest you modify to the RRC steering box, outside of the frame rail, and run a mechanical fan/shroud if you want to be hot-weather, hilly, secure to the point you stop eyeballing your temp gauge. I went through 2 radiators, 2 intercoolers, 4 electric fan combos and never got stable enough to tow my trailer over passes. Now I can go all day, even at 75mph.

If you want advice on the Electric options, I am not your guy. Sorry. I don't believe in them with this motor. I didn't even drain my system when I swapped to the mechanical and all my issues went away.

Now only thing I struggle with is towing from a stop up a steep hill and getting the turbo up to speed to generate some torque without rev'ing a burning the clutch to hell (I am a manual....).

Last edited:

Good to know. I have never been a 'fan' of electric fans either. The shroud is also incredibly important and increases efficiency a ton. I will remeasure again and see if I can fit a mechanical fan, even a smaller blade one may be better than electric. In California, it is consistently over 100 deg in the summer and lots of hills!

dkemm

Well-known member

I agree with Chris! Went through a couple different FMIC, radiator, E-fan combos prior to mechanical salvation. Living in NM, have desert temps and elevation going against me. (Re)building a fan shroud, so none on there and thermostat has yet to stay full open — temp diff between Murphy gauge and seperate gauge (from thermostat housing) is about 10-15degrees (lower at thermostat)Good to know. I have never been a 'fan' of electric fans either. The shroud is also incredibly important and increases efficiency a ton. I will remeasure again and see if I can fit a mechanical fan, even a smaller blade one may be better than electric. In California, it is consistently over 100 deg in the summer and lots of hills!

Cummins should really provide stronger recommendation for mechanical over electrical

MountainD

Technical Excellence Contributor

Important little PSA for those that swap to the aluminum oil pan. I designed the position of the engine with the plastic oil pan in place. Then later, I swapped to the aluminum pan. I am very happy with the aluminum pan with the biggest differences being that (1) it is not plastic. and (2) that it accepts more oil and that is never, imho, a bad thing overall. It takes a lot of oil, though. About 9 qts with the filter change. HOWEVER...

What you see in this pic is where the oil pan is hitting the side of the diff before the bump stop interacts with the axle, so basically, not doing it's job. I had already vetted the interference before I put in the front springs/shocks to make sure this didn't happen when I installed the engine block, however, due to the extended height of the oil pan, I was not so thorough after the aluminum pan swap. So not it is touching and only a matter of another hit of two before it could foreseeably have an issue. Simple fix---I am already using an extended 80mm bump stop, so I will just build up the axle landing plate to have the bump stop hit before the oil pan does---but good to know for anyone that does this swap after the engine is in if they set their geometry to the plastic pan. I should have done a better job of vetting this originally when I swapped. No real harm, but that was just luck.

My plan right now is to secure a piece of delrin cutting board over the axle's landing pad. Maybe weld on a 3/8" landing pad eventually, not sure. I'll figure that out shortly when the garage is not so bloody cold. Woke up to -6F this morning...

What you see in this pic is where the oil pan is hitting the side of the diff before the bump stop interacts with the axle, so basically, not doing it's job. I had already vetted the interference before I put in the front springs/shocks to make sure this didn't happen when I installed the engine block, however, due to the extended height of the oil pan, I was not so thorough after the aluminum pan swap. So not it is touching and only a matter of another hit of two before it could foreseeably have an issue. Simple fix---I am already using an extended 80mm bump stop, so I will just build up the axle landing plate to have the bump stop hit before the oil pan does---but good to know for anyone that does this swap after the engine is in if they set their geometry to the plastic pan. I should have done a better job of vetting this originally when I swapped. No real harm, but that was just luck.

My plan right now is to secure a piece of delrin cutting board over the axle's landing pad. Maybe weld on a 3/8" landing pad eventually, not sure. I'll figure that out shortly when the garage is not so bloody cold. Woke up to -6F this morning...

donb

0

Bummer!

I am going to start breaking my 110 down for paint and have been thinking of doing the same engine mounts that you did while I have everything apart. Adding to that list was a swap from the plastic pan to aluminum so this is good timing.

I think my engine is mounted higher so I may be ok. Any chance you remember how much taller the aluminum pan is over the plastic? Although it looks like its the wider shape that is giving the issue.

I am going to start breaking my 110 down for paint and have been thinking of doing the same engine mounts that you did while I have everything apart. Adding to that list was a swap from the plastic pan to aluminum so this is good timing.

I think my engine is mounted higher so I may be ok. Any chance you remember how much taller the aluminum pan is over the plastic? Although it looks like its the wider shape that is giving the issue.

LOL it's a balmy 18 degrees in Golden!No clue, but if you don’t mind waiting a couple days, I’ll pull some measurements. It’s sub zero right now and I’m COLD!

donb

0

No clue, but if you don’t mind waiting a couple days, I’ll pull some measurements. It’s sub zero right now and I’m COLD!

I don't mind at all - and would really appreciate the measurements!

Is the R2.8 starting fine in the cold or is it in hibernation for the winter?

MountainD

Technical Excellence Contributor

Seems to start just fine, but I’m not driving it when it’s this cold. Dtown hit a low of -18 last night and a high of 33– new Denver record of 51 degree variant. Roads suck. Hard pack and ice. The reason I don’t take it is the mud terrain Tires and it’s high CG. not enough traction to avoid the dipships. I’ve started down to freezing, but haven’t tried sub zero. I also run my webasto engine block coolant heater before starting, just turn it on 10 minutes prior. Works great, trucks garaged though. The LS D90 starts fine sub zero…