acheck

Well-known member

Do you ever feel like your phillips #2 screw driver feels a bit loose in the "phillips" head screws on your Defender? Are they rounding out a bit and occasionally slipping?

Introducing the Pozidriv screw:

What Is Pozidriv?

Pozidriv, commonly spelled incorrectly as “Pozidrive”, is an improved variation on the Phillips drive design. After the patent for the Phillips head expired, the company GKN Screws and Fasteners created the Pozidriv design.

The Pozidriv drive style was originally formed to address the largest issue Phillips heads are prone to: cam-out. Cam-out is defined as the slipping out of a drive recess that occurs when torque exceeds a certain limit. The Pozidriv drive style has the same self-centering design of a Phillips drive style but improves upon the two following factors:

While we at Albany County Fasteners do NOT recommend using the improper drive style on a screw, technically speaking you can. A Phillips drive style fits into a Pozidriv drive recess decently when using the right size. It’s important to note that even if the Phillips does fit snugly into the drive recess, it is still much more likely to strip or cam-out than when using the proper driver.

Alternatively, you can attempt to remove a Phillips screw with a Pozidriv drive but they do not fit into the Phillips drive recess snugly and are much more likely to slip or damage the recess during removal.

Where Are Pozidriv Screws Used?

Pozidriv screws can be used just about anywhere, although they are not nearly as popular as standard Phillips screws. Over the years, many other drive styles, such as the Torx and Robertson, have come out as being more reliable than the Phillips drive style at preventing cam-out and stripping. The Phillips drive is still extremely popular in manufacturing due to its self-centering design but is starting to lose popularity for manual applications due to other drive styles having a better design.

Benefits of the Pozidriv Drive Style

As an improvement on the Phillips drive style, the main benefit of using the Pozidrive is the increased torque without the increased risk of cam-out. Pozidriv screws can handle significantly more torque on the fastener recess than a Phillips drive can.

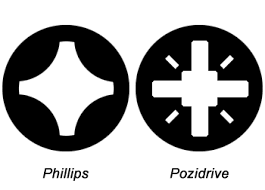

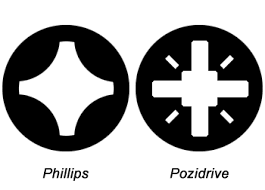

How Do You Identify A Pozidriv Screw?

While Phillips and Pozidriv screws look similar, Pozidriv are actually quite easy to recognize at a glance. This is due to four notches marked into the head of the Pozidriv screw that are not present in the Phillips Head Screw.

the above taken from https://www.albanycountyfasteners.c...at-is-pozidriv-is-it-different-from-phillips/

A set of PZ screwdrivers and bits makes a world of difference when working on your Defender and is not expensive to obtain:

https://www.amazon.com/GEARWRENCH-80061-Piece-Material-Screwdriver/dp/B000UH282Q/ref=sr_1_4?crid=2MEX0J4S4V9IW&keywords=pozidriv+screwdriver+set&qid=1581440103&s=hi&sprefix=pozidriv+screw,tools,152&sr=1-4

This set (or similar) should be in every Land Rover owner's toolbox (PZ used extensively on all coil sprung and P38 models). You will be amazed the first time using the correct tool for the fastener.

I'll follow up below with a few personal favorite Pozidriv tools of mine.

Introducing the Pozidriv screw:

What Is Pozidriv?

Pozidriv, commonly spelled incorrectly as “Pozidrive”, is an improved variation on the Phillips drive design. After the patent for the Phillips head expired, the company GKN Screws and Fasteners created the Pozidriv design.

The Pozidriv drive style was originally formed to address the largest issue Phillips heads are prone to: cam-out. Cam-out is defined as the slipping out of a drive recess that occurs when torque exceeds a certain limit. The Pozidriv drive style has the same self-centering design of a Phillips drive style but improves upon the two following factors:

- Increased torque without cam-out

- Greater surface contact engagement between the drive and the recess in the fastener head making it harder to slip when installed correctly

While we at Albany County Fasteners do NOT recommend using the improper drive style on a screw, technically speaking you can. A Phillips drive style fits into a Pozidriv drive recess decently when using the right size. It’s important to note that even if the Phillips does fit snugly into the drive recess, it is still much more likely to strip or cam-out than when using the proper driver.

Alternatively, you can attempt to remove a Phillips screw with a Pozidriv drive but they do not fit into the Phillips drive recess snugly and are much more likely to slip or damage the recess during removal.

Where Are Pozidriv Screws Used?

Pozidriv screws can be used just about anywhere, although they are not nearly as popular as standard Phillips screws. Over the years, many other drive styles, such as the Torx and Robertson, have come out as being more reliable than the Phillips drive style at preventing cam-out and stripping. The Phillips drive is still extremely popular in manufacturing due to its self-centering design but is starting to lose popularity for manual applications due to other drive styles having a better design.

Benefits of the Pozidriv Drive Style

As an improvement on the Phillips drive style, the main benefit of using the Pozidrive is the increased torque without the increased risk of cam-out. Pozidriv screws can handle significantly more torque on the fastener recess than a Phillips drive can.

How Do You Identify A Pozidriv Screw?

While Phillips and Pozidriv screws look similar, Pozidriv are actually quite easy to recognize at a glance. This is due to four notches marked into the head of the Pozidriv screw that are not present in the Phillips Head Screw.

the above taken from https://www.albanycountyfasteners.c...at-is-pozidriv-is-it-different-from-phillips/

A set of PZ screwdrivers and bits makes a world of difference when working on your Defender and is not expensive to obtain:

https://www.amazon.com/GEARWRENCH-80061-Piece-Material-Screwdriver/dp/B000UH282Q/ref=sr_1_4?crid=2MEX0J4S4V9IW&keywords=pozidriv+screwdriver+set&qid=1581440103&s=hi&sprefix=pozidriv+screw,tools,152&sr=1-4

This set (or similar) should be in every Land Rover owner's toolbox (PZ used extensively on all coil sprung and P38 models). You will be amazed the first time using the correct tool for the fastener.

I'll follow up below with a few personal favorite Pozidriv tools of mine.