lordhelemt

Well-known member

I pretty much finished rebuilding my lt230 and wanted to share a few tips for anyone looking to rebuild their case.

The job isn’t particularly difficult but it did take some effort to clean everything and it does require a few speciality tools, which is where the tips come in.

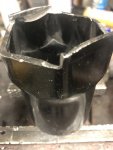

The roller bearing on the rear output shaft is held in place with a 2 sided nut. Apparently the tool is pretty expensive but a socket is necessary to achieve the correct torque setting. I copied an idea I found online where you cut a hub socket to make a tool that would work.

Second is setting the preload on the intermediate gear spacer. A special tool is required but it can be done with a spring balance and length of rope. I wasn’t too keen on using a spring balance but saw online how to make a tool so the preload can be set with a torque meter. I cut the hub side of a 10 spline axel (Thanks Bobeck) and 1” 12point socket. This fits perfectly into the output shaft so you can set the correct preload on that spacer.

When trying to place the intermediate gear set the bearings kept falling out so I used a little grease to hold them in place while fitting the gears.

The job wasn’t too bad and I think it’s built up correctly. I can wait to free up some time, get the box back in the 90, and enjoy it this winter.

Ihope this helps anyone needing to rebuild their case.

The job isn’t particularly difficult but it did take some effort to clean everything and it does require a few speciality tools, which is where the tips come in.

The roller bearing on the rear output shaft is held in place with a 2 sided nut. Apparently the tool is pretty expensive but a socket is necessary to achieve the correct torque setting. I copied an idea I found online where you cut a hub socket to make a tool that would work.

Second is setting the preload on the intermediate gear spacer. A special tool is required but it can be done with a spring balance and length of rope. I wasn’t too keen on using a spring balance but saw online how to make a tool so the preload can be set with a torque meter. I cut the hub side of a 10 spline axel (Thanks Bobeck) and 1” 12point socket. This fits perfectly into the output shaft so you can set the correct preload on that spacer.

When trying to place the intermediate gear set the bearings kept falling out so I used a little grease to hold them in place while fitting the gears.

The job wasn’t too bad and I think it’s built up correctly. I can wait to free up some time, get the box back in the 90, and enjoy it this winter.

Ihope this helps anyone needing to rebuild their case.

Attachments

-

06C5A8EE-63FB-468C-A9E7-8BFDD89DBFE0.jpeg115.2 KB · Views: 311

06C5A8EE-63FB-468C-A9E7-8BFDD89DBFE0.jpeg115.2 KB · Views: 311 -

283E12A4-5CEB-4C29-A953-3D8335AB0D1B.jpeg119.8 KB · Views: 306

283E12A4-5CEB-4C29-A953-3D8335AB0D1B.jpeg119.8 KB · Views: 306 -

A8FD37CC-7C3B-48B1-8475-48A0D13F886D.jpeg166.9 KB · Views: 300

A8FD37CC-7C3B-48B1-8475-48A0D13F886D.jpeg166.9 KB · Views: 300 -

7398490B-9CB3-45D4-8374-15EDF97B4750.jpeg148.5 KB · Views: 318

7398490B-9CB3-45D4-8374-15EDF97B4750.jpeg148.5 KB · Views: 318 -

5C968ED3-D4C5-42B7-8EB3-CB3192C7C053.jpeg238.7 KB · Views: 293

5C968ED3-D4C5-42B7-8EB3-CB3192C7C053.jpeg238.7 KB · Views: 293 -

301FF6A3-4561-463F-80E7-C8CBA8AA02DE.jpeg214.7 KB · Views: 345

301FF6A3-4561-463F-80E7-C8CBA8AA02DE.jpeg214.7 KB · Views: 345