You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2.5NA to 300tdi to R2.8

- Thread starter Spikemd

- Start date

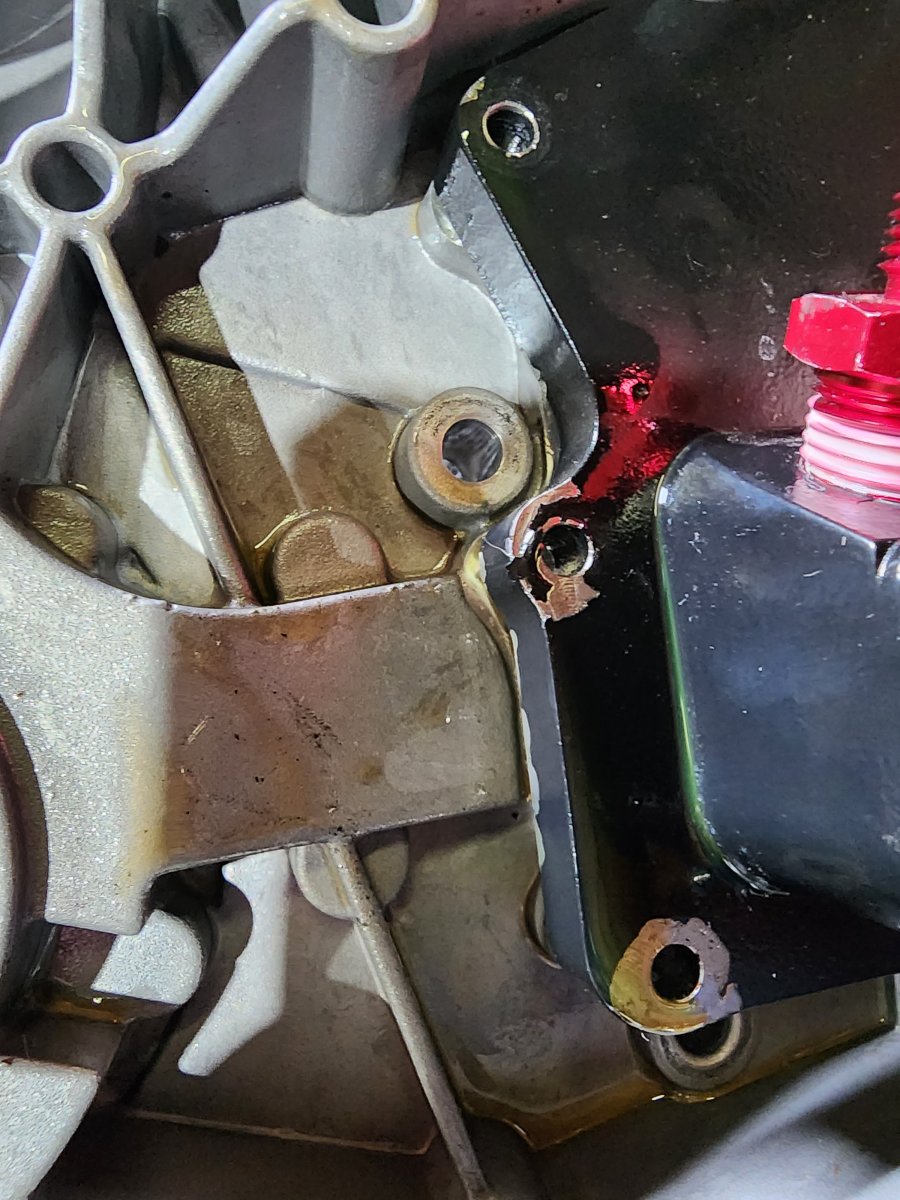

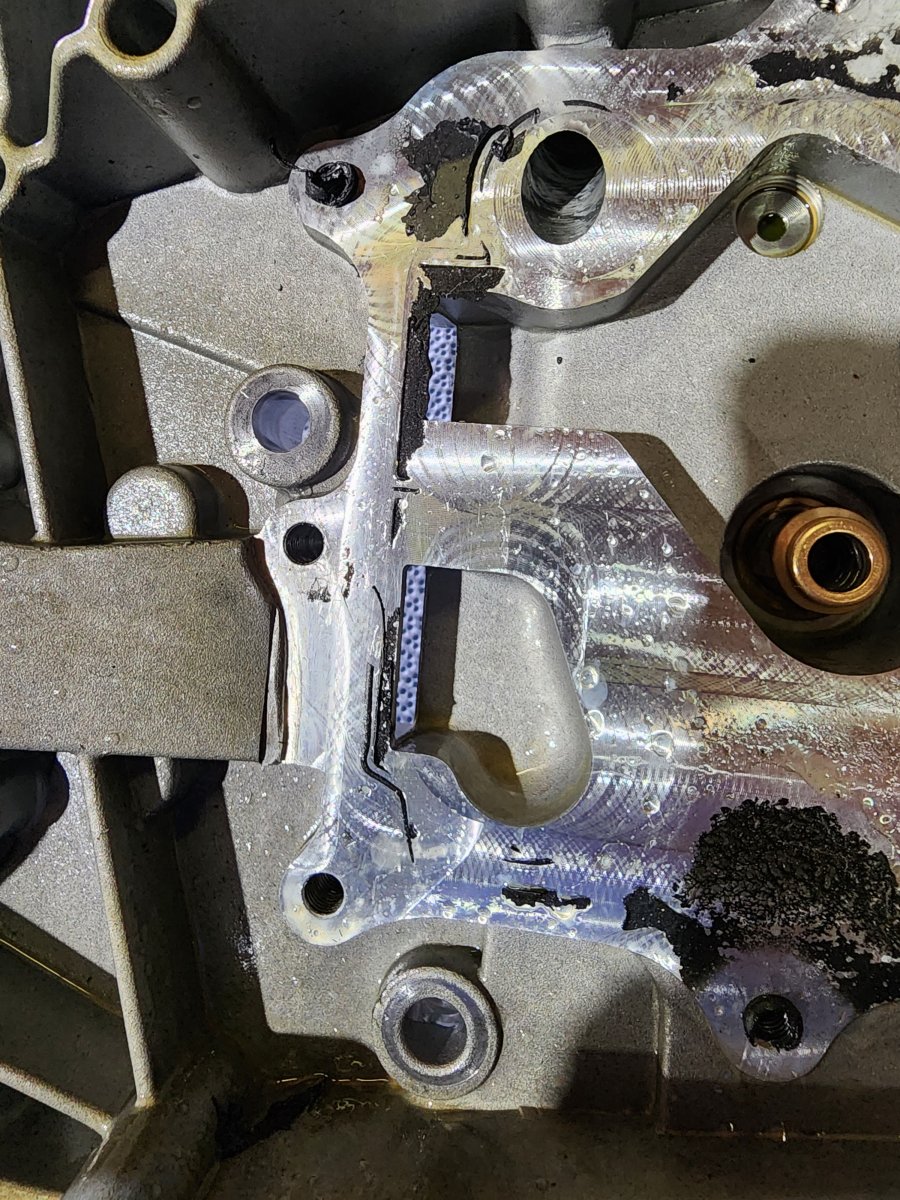

Here are some pics of the remote oil cooler plate from Chad at QuickDraw that wasted weeks of my time. Basically, the plate was machined wrong and needs more cutout on the side. I have an early engine but also matched it up to a later plate with same results. If you buy one, talk to Chad an be sure he has fixed it or machine yours out before fitting. The original design would crimp the front cover casting where it has a small lip. I didnt see it initially and it cracked on the inside of the front cover making it hard to diagnose where the leak was coming from.

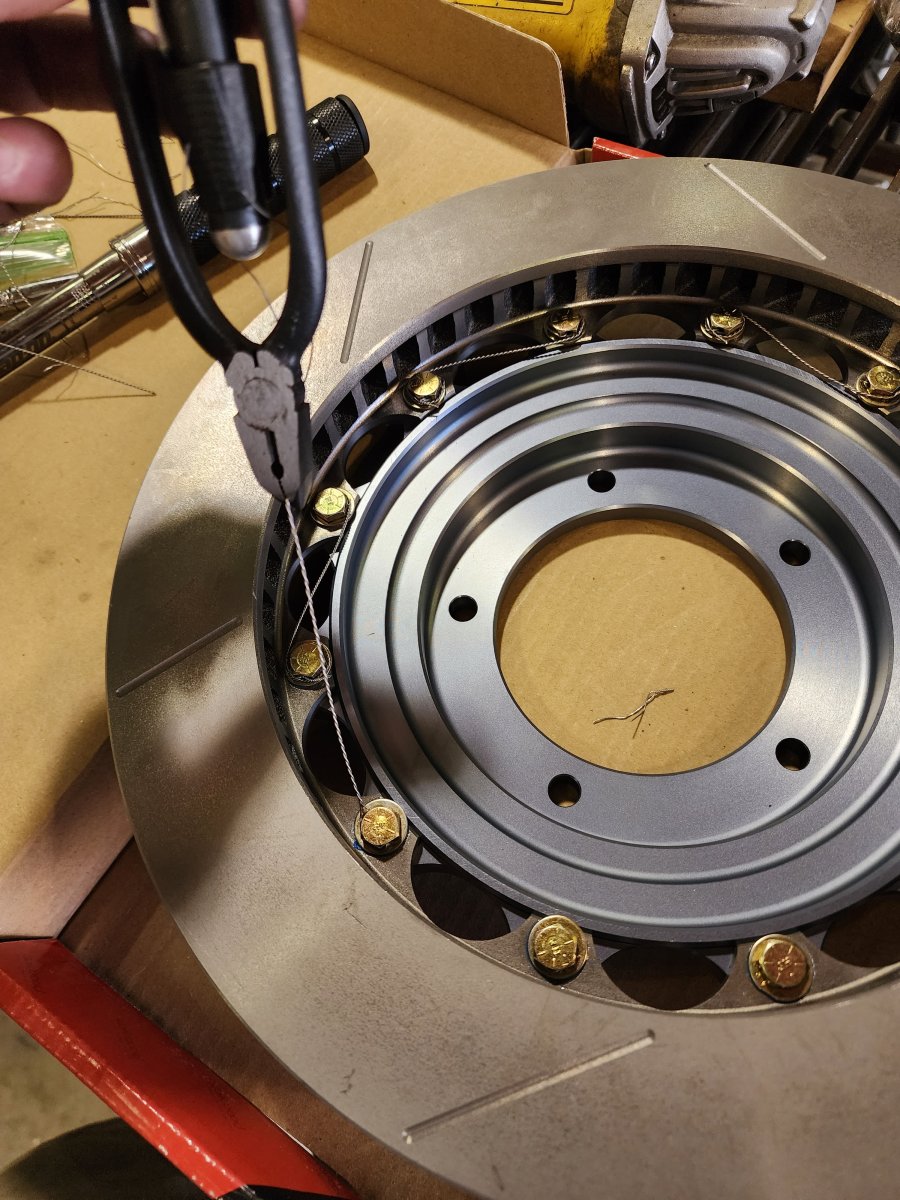

Once I got all the leaks taken care off, I needed to upgrade the brakes to stop these massive 37s. I dont think I have room for hydroboost with my coilovers and hoops for suspension.

Kit is from Forbyn Brothers in Placerville, CA with top quality adapters. 13 inch floating rotors with large 6 piston calipers for front and 4 pistonfor rear. They also make adapter kits for going from drum to rotors on Salisbury and for fitting to Series vehicles.

Safety wire is tedious but incredibly important. A safety wire tool makes life easier for twisting. Brakes look awesome!

Kit is from Forbyn Brothers in Placerville, CA with top quality adapters. 13 inch floating rotors with large 6 piston calipers for front and 4 pistonfor rear. They also make adapter kits for going from drum to rotors on Salisbury and for fitting to Series vehicles.

Safety wire is tedious but incredibly important. A safety wire tool makes life easier for twisting. Brakes look awesome!

Last edited:

Wow, haven't posted in a long time. Engine was installed and working well thought would get hot on uphills when outside temps were over 100. Brake booster failed so installed Hydroboost took her on the Rubicon and beat her up. Broke rear passenger leaf spring perch. Trail weld and ratchet straps from my axle to the frame got me home. Those leafs were the last piece of original equipment on the truck. New leafs installed now.

Attachments

Have been driving her around for a bit. Power is good but still gets hot on uphills and temps over 100F. Due to space issues with my power steering box, a mechanical fan doesn't look like it will work. Need to upgrade my electrical fans and build a good shroud. Was just driving her around town mostly after Rubicon and threw a major code (001) low oil, and immediately, she starting making noises. I filled up with 2 quarts! WTF? Didn't see any leaks? Could've sworn u checked the levels recently. Burning oil? Started making more noise and towed it to the shop. Dropped the oil pan and nightmare came true...connecting rod bearing on cylinder 3 was toasted...ugh...

Out comes the engine. What luck I have had...toasted 2 engines in this truck...am I cursed? First engine didn't even make it home from the shop, but that was a used 300tdi and looked like it had a plugged oil or water hole. The whole reason I went with the Cummins was to not deal with engine failures!

I talked to Steve Sanders, but he and Brittany have left Cummins and the program. But he still got me in touch with someon at Cummins. Unfortunately, the warranty starts at the time of delivery and my engine was delivered in 2018, but sat around for a few years before I bought it. It was an early production engine, which I have heard also had more issues. Anyway, the engine was already out of the vehicle and they wanted the engine info, hours, etc and were not helpful in trying to remedy my situation.

Just a visual inspection of the crank, and I could see it was worn and not reusable. I did find a set of 0.5 bearings that could be used if we machined the crank, but seemed like too much work and guessing. Finding any internal parts for this engine was a supreme challenge. We took the block to a shop and they said everything looked good.

Not much info out there about these engines, but basically is it an ISF 2.8 engine that is finished in the states with the electronics and ancillaries. The block and head are manufactured at the same Cummins plant as the other million ISF engines sold to tractors/excavators/generators and the Futon Chinese pickup trucks. Of course, buying a whole long block is a bit expensive to ship from China, so I started to look at parts and rebuild kits. Cranks are around $900, connecting rods $100, bearings $200, gasket set $200. I found a whole rebuild kit on ebay for $1450 and it includes crank, 4 pistons, connecting rods, pins, sleeves, valves, pretty much everything. So I took a a gamble and bought the kit.

Just a visual inspection of the crank, and I could see it was worn and not reusable. I did find a set of 0.5 bearings that could be used if we machined the crank, but seemed like too much work and guessing. Finding any internal parts for this engine was a supreme challenge. We took the block to a shop and they said everything looked good.

Not much info out there about these engines, but basically is it an ISF 2.8 engine that is finished in the states with the electronics and ancillaries. The block and head are manufactured at the same Cummins plant as the other million ISF engines sold to tractors/excavators/generators and the Futon Chinese pickup trucks. Of course, buying a whole long block is a bit expensive to ship from China, so I started to look at parts and rebuild kits. Cranks are around $900, connecting rods $100, bearings $200, gasket set $200. I found a whole rebuild kit on ebay for $1450 and it includes crank, 4 pistons, connecting rods, pins, sleeves, valves, pretty much everything. So I took a a gamble and bought the kit.

I talked to Steve Sanders, but he and Brittany have left Cummins and the program. But he still got me in touch with someon at Cummins. Unfortunately, the warranty starts at the time of delivery and my engine was delivered in 2018, but sat around for a few years before I bought it. It was an early production engine, which I have heard also had more issues. Anyway, the engine was already out of the vehicle and they wanted the engine info, hours, etc and were not helpful in trying to remedy my situation.

Just a visual inspection of the crank, and I could see it was worn and not reusable. I did find a set of 0.5 bearings that could be used if we machined the crank, but seemed like too much work and guessing. Finding any internal parts for this engine was a supreme challenge. We took the block to a shop and they said everything looked good.

Not much info out there about these engines, but basically is it an ISF 2.8 engine that is finished in the states with the electronics and ancillaries. The block and head are manufactured at the same Cummins plant as the other million ISF engines sold to tractors/excavators/generators and the Futon Chinese pickup trucks. Of course, buying a whole long block is a bit expensive to ship from China, so I started to look at parts and rebuild kits. Cranks are around $900, connecting rods $100, bearings $200, gasket set $200. I found a whole rebuild kit on ebay for $1450 and it includes crank, 4 pistons, connecting rods, pins, sleeves, valves, pretty much everything. So I took a a gamble and bought the kit.

Tear down of the whole block only took about 4 hours. Amazingly simple engine.

Unpacked the rebuild kit and measured everything. The new pistons with 0.5mm smaller assuming to fit in the sleeves if used. Since my block was fine, I was going to reuse the pistons. The new connecting rods were slightly different and not the same markings as the pic in the listing. So I swapped out all connecting rods for new. Dropped in new crankshaft, torqued down and clearance for all bearings looked good. The main thrust bearing was different and one piece Compared to 3 piece like the original. With some coaxing, it fell into place and tolerances look good. Crank in and spinning freely. Finally some progress!!

Unpacked the rebuild kit and measured everything. The new pistons with 0.5mm smaller assuming to fit in the sleeves if used. Since my block was fine, I was going to reuse the pistons. The new connecting rods were slightly different and not the same markings as the pic in the listing. So I swapped out all connecting rods for new. Dropped in new crankshaft, torqued down and clearance for all bearings looked good. The main thrust bearing was different and one piece Compared to 3 piece like the original. With some coaxing, it fell into place and tolerances look good. Crank in and spinning freely. Finally some progress!!

I bought the new Cummins aluminum oil pan. It requires a new dipstick and plug for the other side. Wow, it is so much bigger! Probably twice the capacity for oil which translates to lower oil temps and more piece of mind. Its tough to appreciate in the photos, but the front section is more than twice as deep. Only issue I may have is clearance with the axle as I've seen other builds with issues. I will find out when I install it. Also looking into using the other dipstick slot for an oil level sensor or warning.

I currently have a cylindrical remote oil cooler which caused me a lot of headaches because it wasn't manufactured correctly from Quickdraw and cracked my front cover. I may go back to the factory stacked cooler with this larger capacity oil pan to eliminate extra points of failure.

I currently have a cylindrical remote oil cooler which caused me a lot of headaches because it wasn't manufactured correctly from Quickdraw and cracked my front cover. I may go back to the factory stacked cooler with this larger capacity oil pan to eliminate extra points of failure.

KW1985def110

Well-known member

Did you happen to check the piston protrusion at top dead center ? Does the new kit match?

That sucks. I’ve heard of a few catastrophic failures of these. Have you diagnosed the root cause of the oil loss?

Total bummer to have an engine go bad that fast.

Measuring piston protrusion makes a ton of sense if using mismatched pistons (old) and rods (new). Should all be the same, but still worth confirming.

If no apparent leaks, then it does seem to suggest you're burning oil. Which would make me nervous about reusing old rings, unless you have a good explanation for another route that oil is getting into the combustion chamber.

Measuring piston protrusion makes a ton of sense if using mismatched pistons (old) and rods (new). Should all be the same, but still worth confirming.

If no apparent leaks, then it does seem to suggest you're burning oil. Which would make me nervous about reusing old rings, unless you have a good explanation for another route that oil is getting into the combustion chamber.

KW1985def110

Well-known member

If it was burning that much oil, you would think it would be noticeable out the exhaust?