MountainD

Technical Excellence Contributor

So, first and foremost---I used the Stubby R380 in my build. most folks I know are using the long nose version, if that transmission at all. So the position of the oil pan in relationship to the front diff will vary based on position. Also, my DIFF, not the axle, intersected the pan which makes sense from the photo as it is on the diagonal of the corner. So take that into account. You can see that there is a protrusion of the pan where it hit and then the pan is actually more narrow an inch or two back, so by moving the engine forward you would have a little more clearance.

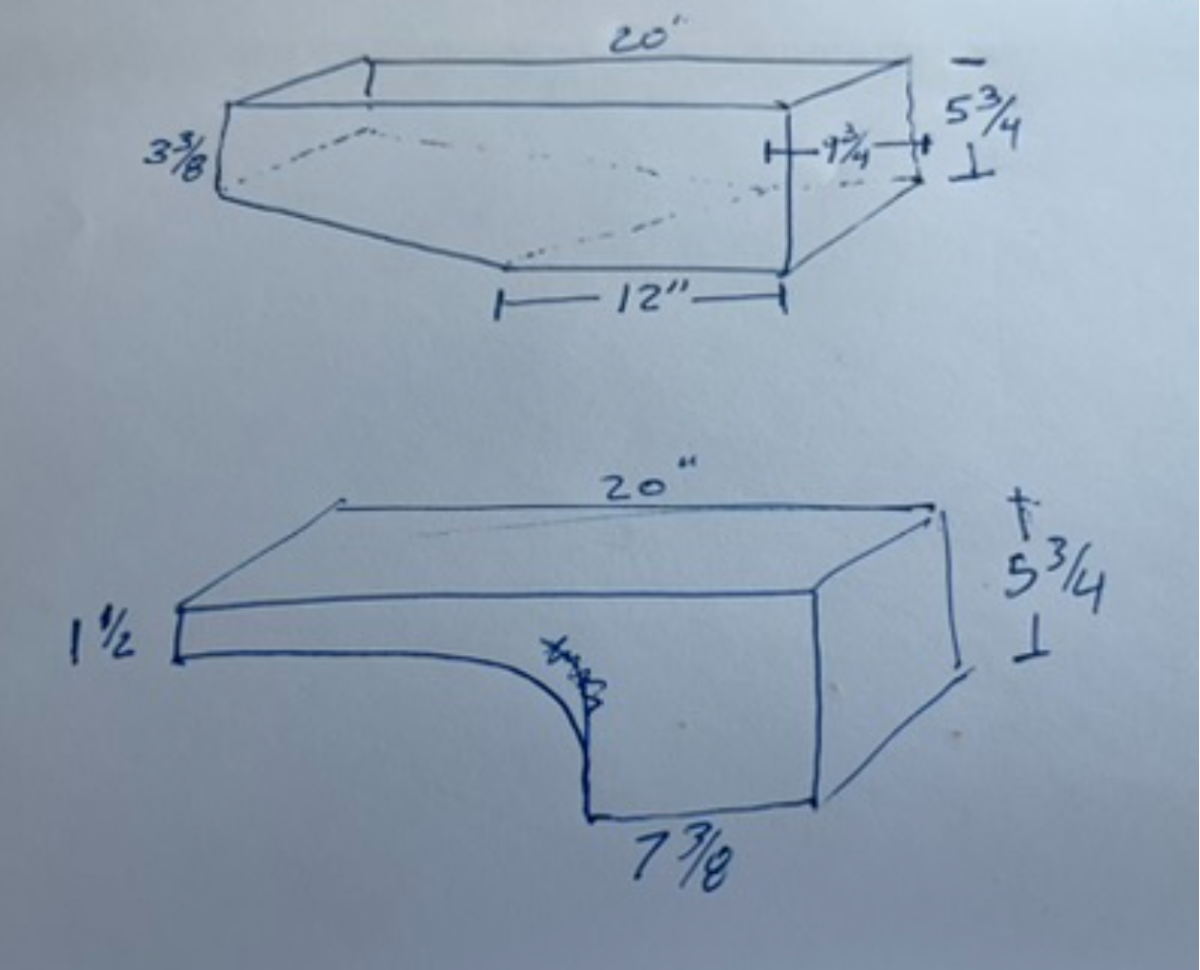

The pans are drastically different shapes which accounts for the sizable increase in the oil capacity. Here are the ROUGH dimensions---with the plastic pan on the bottom.

The pans are drastically different shapes which accounts for the sizable increase in the oil capacity. Here are the ROUGH dimensions---with the plastic pan on the bottom.