Cutting the wire will make zero difference.... ....You will read within a few degrees 100% of the time.

^ ^ ^ I've been inclined to believe this version of things, I just know so little of this stuff that when the original instructions say NOT TO CUT, I tend to go with what they say. HOWEVER, since to pull apart my dash and extract the coil, and get it all back together again really will mean a lot of work (and I'm afraid it will damage the plastic pieces) I think I will try it like this: The original VDO wires have a set of connecter loops at the sensor end. Once you've strung it through the bulkhead, this is how you actually connect the last 12" of wire and sensor probe to the main 10 feet of wire. I can't see how it would hurt to use the new sensor probe, 12" of wire, connect to the main VDO line at that point. In the end I might have a centimeter of difference, but virtually the same connection.

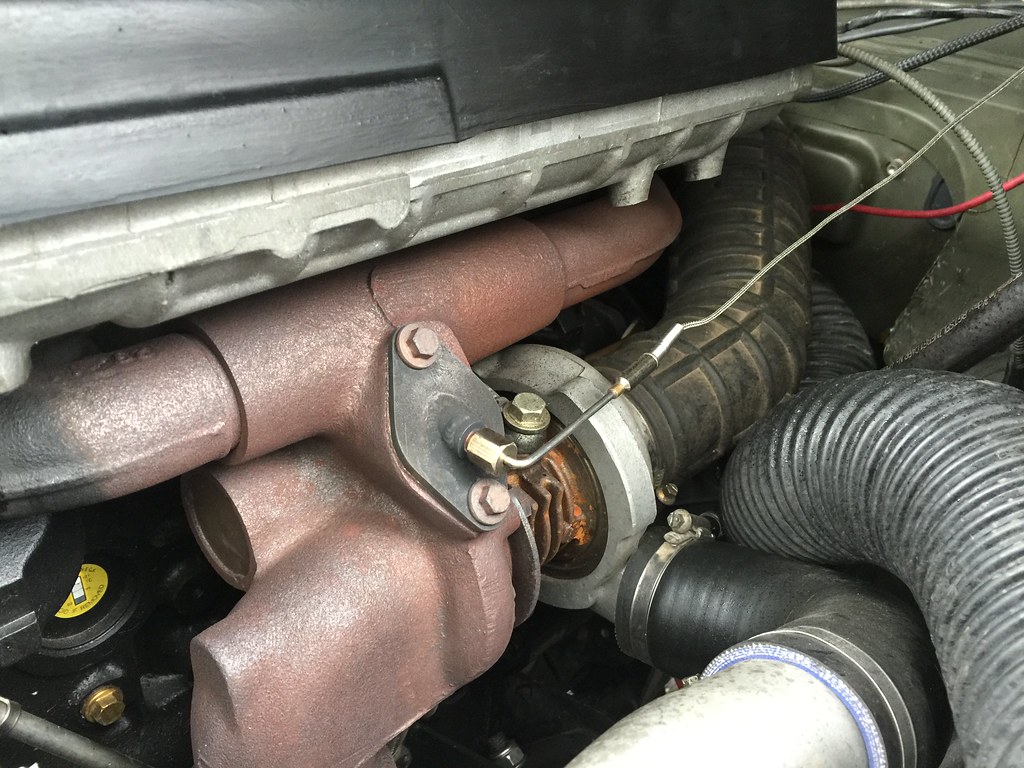

That said, my plan right now is to get the blanking plate tapped, or replaced. Reinstall my current sensor to it's maximum depth -- I think I can get another 1/2 inch at least, if I tap the bung correctly. Test to see if I notice a difference, and I watch it close enough that I can tell the difference between the types of fuel I'm using, so I should be able to tell if extending the probe shows quicker and more accurate results.