Napalm00

Technical Excellence Contributor

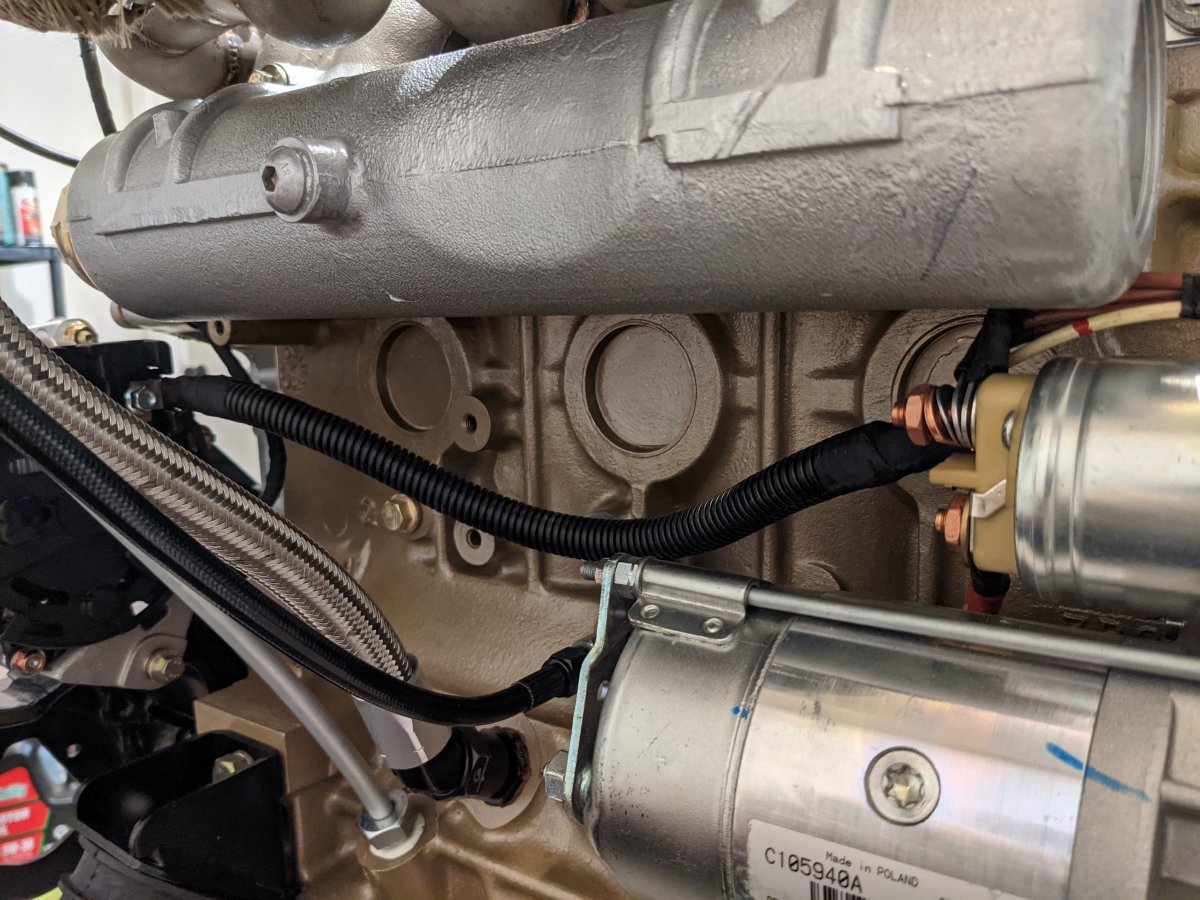

Made some charging cables.

The way I run this is that I make this 4 gauge cable with two 90 degree ends. Little bit of marine heat shrink and then they get a corrugated jacket with some Tessa tape. I run this in conjunction with the existing tiny little 12 gauge wires that run the rest of the truck and work through the multi plug to run the main loom. Since all my high power stuff is all on separate circuits outside of the main loom this allows me to keep the existing wiring in the truck and have an upgraded charging circuit to take advantage of the 100 amp alternator.

The way I run this is that I make this 4 gauge cable with two 90 degree ends. Little bit of marine heat shrink and then they get a corrugated jacket with some Tessa tape. I run this in conjunction with the existing tiny little 12 gauge wires that run the rest of the truck and work through the multi plug to run the main loom. Since all my high power stuff is all on separate circuits outside of the main loom this allows me to keep the existing wiring in the truck and have an upgraded charging circuit to take advantage of the 100 amp alternator.