Or a good set for you so you don’t have to hear the complaining as you drive.Get a pair of soft ear plugs, they go a long way..

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What have you done to your DEFENDER today?

- Thread starter javelinadave

- Start date

I've been putting this one off for a while now. I finally got around to replacing the leaky rear brake proportional valve.

I'm not sure what would go bad in these to cause leaks...

if anyone decides to DIY this, here are couple observations:

and brake fluid was eating a bit of the paint.

shiniest thing in the engine bay right now.

old leaky and new... hopefully no leaky.

I'm not sure what would go bad in these to cause leaks...

if anyone decides to DIY this, here are couple observations:

- the bolt holding the valve is inside the cab, the passenger side footwell. My truck has a 1/2" (!) bolt & nut. You'll need someone/something to hold the bolt inside to loosen the nut.

- the compression nuts are 3x 11mm & 1x 13mm. strongly recommend using flare nut wrenches

- have small container to catch brake fluid after removing the compression nuts. if you get brake fluid on paint (brake fluid eats paint).. make sure to flush with plenty of water after job is done.

- installing the new valve is reverse of removal. Take your time and take a break if you get frustrated. I found it best to put the retaining bolt in last, and start with the 2 bottom compression nuts first. Start by hand-threading all the nuts at least 4 - 5 turns. Without the retaining bolt, you can rotate/tilt the valve a little to help threading by hand much easier. You don't want to cross thread these things. Once you have 4 - 5 hand turns on each of the compression nuts, then put the bolt through.

- Lastly, flush brakes with DOT4 fluid at all 4 corners. Check for leaks.

and brake fluid was eating a bit of the paint.

shiniest thing in the engine bay right now.

old leaky and new... hopefully no leaky.

Oh man is she going to be pissed at you or she rides that thing after you do all this work that is just as fucking loud lol. No really it'll definitely help cut down on the tininess.

I used to work on this D90 that the owner went through and used all of the different Dynamat products. The results were pretty incredible. It was like driving modern non-luxury car on the highway. He did it one section at a time and said the one that made the biggest difference was the hood insulation.

rocky

NAS-ROW Addict

I dynamatted th

Fixed your post so you get to keep your Defender 110 if you did get the Freelander XL.

My wife can't stand the noise in my Defender and keeps bugging me to get a 2020 Defender so here I come to resolve this.

Fixed your post so you get to keep your Defender 110 if you did get the Freelander XL.

Brrrrt

Member

Put on a new galvanized front bumper on my 90 today...the plan is to let it dull out like the chassis. I still need to figure out a decent way to mount a front plate that is secure if anyone has any recommendations for a decent metal license plate bracket?

Attachments

Z.G

Well-known member

Put on a new galvanized front bumper on my 90 today...the plan is to let it dull out like the chassis. I still need to figure out a decent way to mount a front plate that is secure if anyone has any recommendations for a decent metal license plate bracket?

I just put M8 rivnuts in mine, then used aluminum plates to bolt to that and the plate

Steve 110

Member

What kind of gas mileage you getting and at what speedsI started a 7-day road trip from NYC to Arizona in my ‘89 110. The Cummins recently installed by Doug makes a wee bit of a difference on the highway. View attachment 14851

Thx

rocky

NAS-ROW Addict

Put on a new galvanized front bumper on my 90 today...the plan is to let it dull out like the chassis. I still need to figure out a decent way to mount a front plate that is secure if anyone has any recommendations for a decent metal license plate bracket?

how about using a tool box mount? they are designed for c channel trailer chassis?

Nick&Nora

Well-known member

On long, steady stretches of interstate, at 60-65 mph and with the stock tune, 25-26 mpg. Tuned up and running at 70-75, more like 19. It's a 110 with 235/85 KO2s, a front runner rack and a winch. The cargo area was loaded fairly densely up to the top of the second row seats.What kind of gas mileage you getting and at what speeds

Thx

rocky

NAS-ROW Addict

Nothing with my Defender (waiting for parts is so......) but helped a buddy who has his own shop. He's dealing with a customer who a year ago took his Ram 3500 Hemi to a dealer for a new radiator. You know those stories you read about the dangers of mixing cooling fluids causing gritty deposits to form. Its true. Everywhere. Horrible mess. I doubt the radiator despite best efforts will flow as well as it should. The Water pump is a mess. Short of pulling the heads, no way to be 100% sure that you have cleaned it all out. Owner is a builder who also hauls cattle for a 4H. 30k a year. Hard working truck.

Last edited:

Angus

Well-known member

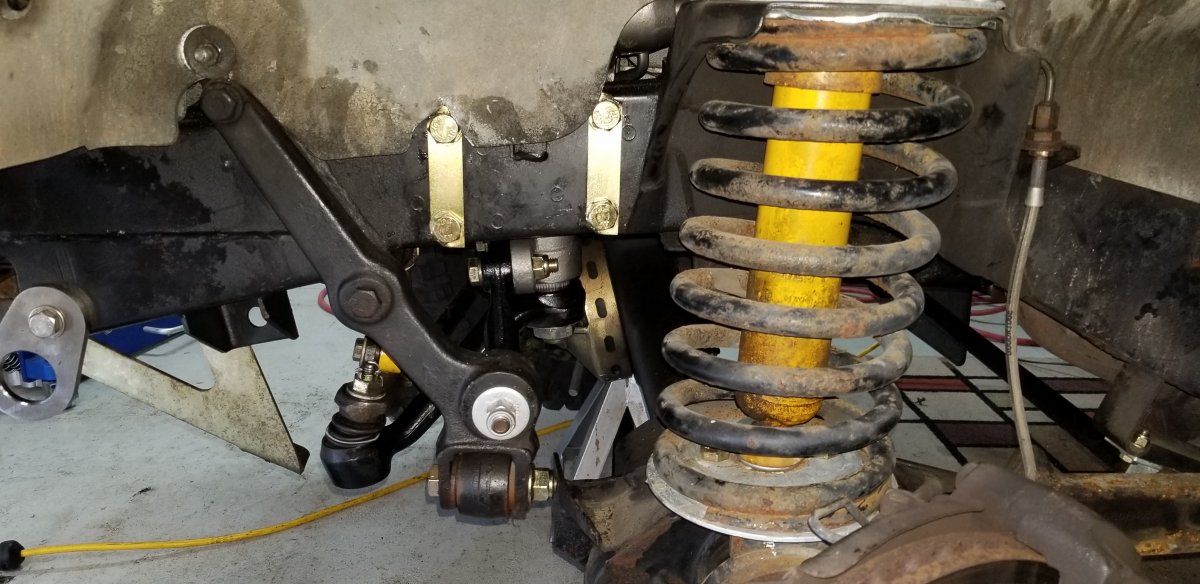

Replaced my leaking steering box with a rebuild. Had a hard time getting the old one oriented to drop out, but the new one went right in. Nice part about a leaky seal is everything is rust proofed and comes right off. Even the pitman arm came off with minimal effort. Also took the chance to replace the hardware and paint the brackets. Not much of the original 1994 left now...

Napalm00

Technical Excellence Contributor

Put on a new galvanized front bumper on my 90 today...the plan is to let it dull out like the chassis. I still need to figure out a decent way to mount a front plate that is secure if anyone has any recommendations for a decent metal license plate bracket?

I just drilled two holes and used some bolts and a couple washers for a standoff

hillstrubl

Founding Member

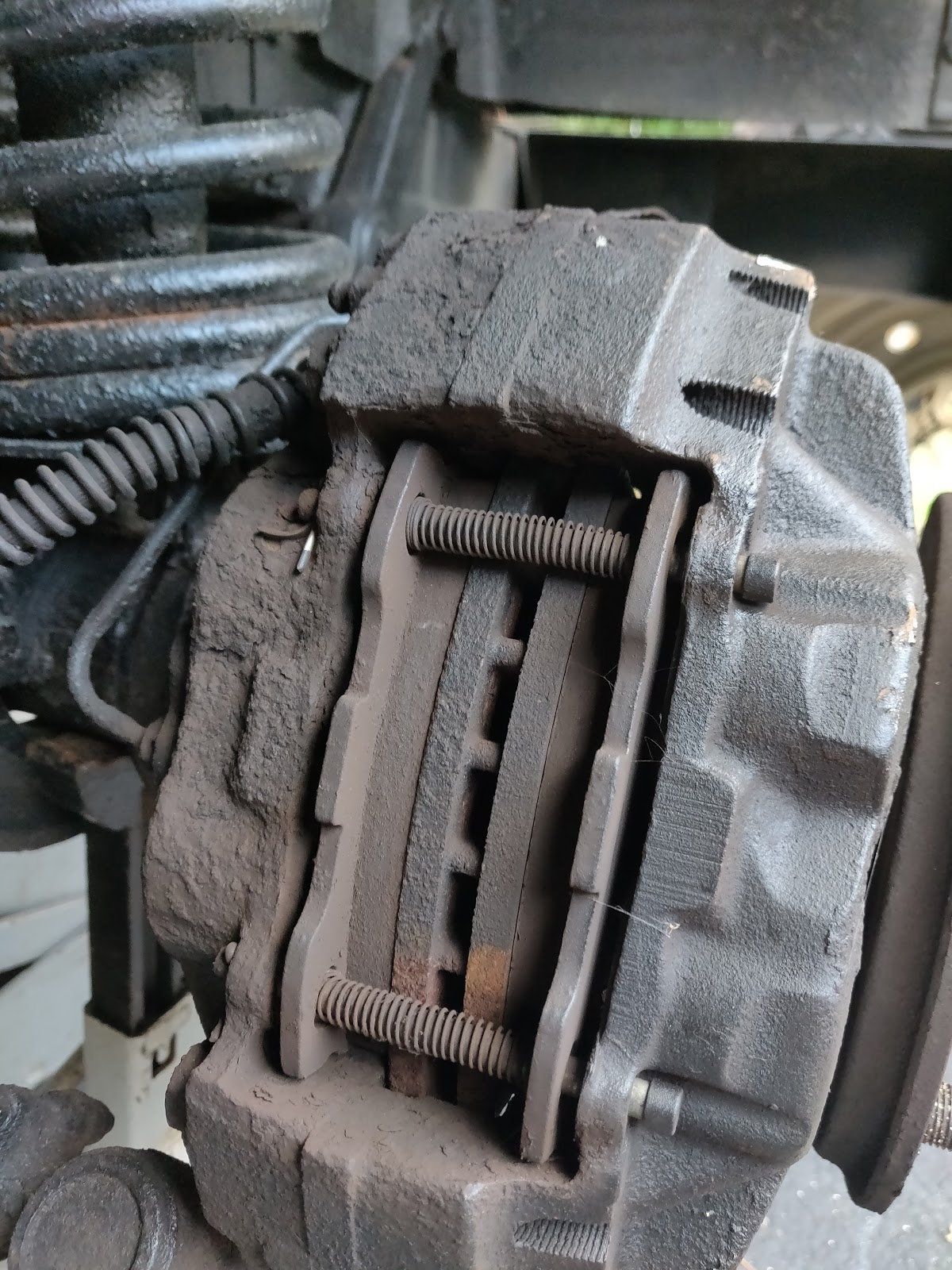

Took the wheels off thinking I was doing brakes because they are squeaking a lot, only to find the pads looked plenty thick and the rotors seemed fine too.. (NVM the crusty calipers, i'll replace those next). So now I'm confused, maybe one of the pads isn't aligned properly and is grabbing the rotor at an angle causing the squeaking?

Napalm00

Technical Excellence Contributor

Mechanically they look fine. They are utterly filthy and are probably squealing because of contamination.

Take the pad out, clean the backs of the pads and the face the piston, thoroughly clean the brake disc, apply anti-squeal paste on the back of the pad and reinstall. Give it a couple nice really hard stops from about 45 miles an hour.

Take the pad out, clean the backs of the pads and the face the piston, thoroughly clean the brake disc, apply anti-squeal paste on the back of the pad and reinstall. Give it a couple nice really hard stops from about 45 miles an hour.

RDavisinVA helped we weld on some motor mounts and even risked inhaling zinc fumes.

I installed the Syncro Gearboxes thermostatic valve for the R380, this will route to a trans cooler when I figure out where to mount it.

Got the tdi crossmember installed using spreader clamps, hammers, a jack and no small amount of swearing.

Trans and t-case are in just waiting for the flywheel to come back from the machine shop.

and the cat slept in a blanket.

I installed the Syncro Gearboxes thermostatic valve for the R380, this will route to a trans cooler when I figure out where to mount it.

Got the tdi crossmember installed using spreader clamps, hammers, a jack and no small amount of swearing.

Trans and t-case are in just waiting for the flywheel to come back from the machine shop.

and the cat slept in a blanket.

I love a freshly resurfaced flywheel. It just makes me think the truck will be smoother and more powerful! Also installed a LOF clutch resplendent in series pastel green.

I didn’t take a picture underneath, but I also installed this SDO high-capacity t-case sump. I had this tapped to accommodate a temp sender. That will allow me to keep an eye on the temps since I plan to do a little towing with this truck.

Oh, and the cat killed Jeff.

I didn’t take a picture underneath, but I also installed this SDO high-capacity t-case sump. I had this tapped to accommodate a temp sender. That will allow me to keep an eye on the temps since I plan to do a little towing with this truck.

Oh, and the cat killed Jeff.

Napalm00

Technical Excellence Contributor

This interesting failure I finally got around to fixing today as part of the Tdi build. On the rear bearing block of 200 and 300 TDI there is a tapped hole that's used to remove the rear bearing block with a slide hammer. On the one that I'm using to make this new motor I found that the tapped hole had been tapped too deeply. so deep in fact that it passes through the oil return galley way for the rear crank. I'm assuming that this motor had a pretty bad oil leak back here because the threaded hole that leads up from the bearing block would only be covered with the rear ladder frame and a small amount of rtv.

I used a set screw and sunk it all the way deep into the hole with a nice basting of 272 loctite. That you keep this oil galley away from bleeding up past and into the threaded hole.

I used a set screw and sunk it all the way deep into the hole with a nice basting of 272 loctite. That you keep this oil galley away from bleeding up past and into the threaded hole.