SaintPanzer

Well-known member

I was hoping the Tech Support guys from my favorite parts supplier would have answered my email by now... but I really want to place an order because I know this probably won't be a "one weekend" project. So:

The time has come to remove and replace my swivel balls. One seal is leaking, so that needs to be replace, and the ball is a bit pitted, so it's probably time. Also, while I'm in there, I will R&R the pads and rotors. I just want to make sure I get everything I need all at once, so I'm not stuck "waiting" with the truck in the air while parts ship.

Does anyone have a complete recommended parts list for the job? I know I want a genuine LR ball... but what else? I'm looking at the parts diagram, and I'm sure I'm going to forget something!

Related: Should I buy extra shims for adjusting the top pin? If so, how many/which ones?

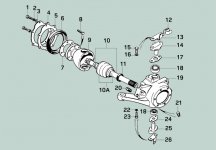

I've checked out a few videos, I have a fish scale, and am expecting a mess. Part of the project will involve pulling the bolt that limits how far the tires turn (the head broke off, bring the heat and some vice grips...) Looking at the below photo, I am thinking 4, 5, 6, 7, 9, 11 (X2), and 18 (X2). Of course, all that, twice, so I can do both sides.

Any other "before you start" advice? I don't have a garage, so this will be done in the driveway... should be entertaining. I will post photos.

The time has come to remove and replace my swivel balls. One seal is leaking, so that needs to be replace, and the ball is a bit pitted, so it's probably time. Also, while I'm in there, I will R&R the pads and rotors. I just want to make sure I get everything I need all at once, so I'm not stuck "waiting" with the truck in the air while parts ship.

Does anyone have a complete recommended parts list for the job? I know I want a genuine LR ball... but what else? I'm looking at the parts diagram, and I'm sure I'm going to forget something!

Related: Should I buy extra shims for adjusting the top pin? If so, how many/which ones?

I've checked out a few videos, I have a fish scale, and am expecting a mess. Part of the project will involve pulling the bolt that limits how far the tires turn (the head broke off, bring the heat and some vice grips...) Looking at the below photo, I am thinking 4, 5, 6, 7, 9, 11 (X2), and 18 (X2). Of course, all that, twice, so I can do both sides.

Any other "before you start" advice? I don't have a garage, so this will be done in the driveway... should be entertaining. I will post photos.