You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Swivel Ball lube questions

- Thread starter Tbaumer

- Start date

MountainD

Technical Excellence Contributor

50/50 90wt and Lucas stabilizer

Why? Why not just use an out of spec viscosity gear oil such as 140? I know the topic of these have been beat to death on Bob's the Oil Guy, but am curious what benefit you are seeing as I have not seen much on the Lucas other than as a thickener (other than their claims, of course).

75/90 for me. And when it leaks, I fix it. I have a rational for this too--for me when submerged in water, I don't want contaminants getting in and the tighter the tolerances the better that will be. For a nice lubricating element like 75/90, which is plenty thick for me and flows well I don't see the point of going thicker. If that stuff can't get out (and your breathers are working right), I am less likely to get stuff in. Many of my friends and I have been stuck in above-hub-height water for a long duration waiting for recovery. Not me, of course, I have never been stuck in my life

I'm in the process of swapping out my front axle on the new 110 to a 1998 disco to get the 24spline center and I am ordering the new gaskets and will be taking out the inner seal as well...

I'm in the process of swapping out my front axle on the new 110 to a 1998 disco to get the 24spline center and I am ordering the new gaskets and will be taking out the inner seal as well...

Why? That is a downgrade. The hub bearings are closer together, giving a weaker hub. The halfshafts are much smaller, making both the shafts and CV joints much weaker. The wider radius arms flex much less.

MountainD

Technical Excellence Contributor

Why? That is a downgrade. The hub bearings are closer together, giving a weaker hub. The halfshafts are much smaller, making both the shafts and CV joints much weaker. The wider radius arms flex much less.

I think you may have read it backwards. My 110 (not new, just new to me) is a 1991 with thick flanges---it is a 10 spline with narrow radius arms. I am going to the 24 spline with thick radius arms... I believe I am going in the right direction

I think you may have read it backwards. My 110 (not new, just new to me) is a 1991 with thick flanges---it is a 10 spline with narrow radius arms. I am going to the 24 spline with thick radius arms... I believe I am going in the right direction

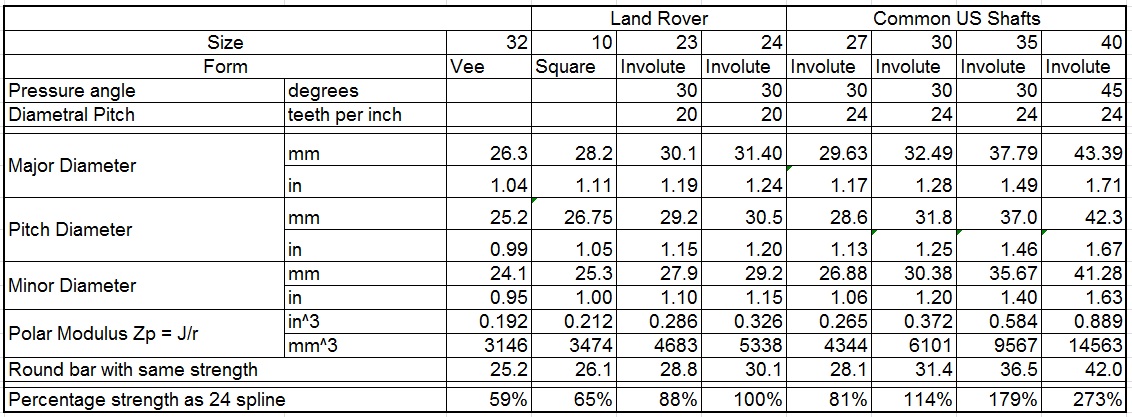

The later 24 spline axles are weaker than the early 10 spline axles.

1) Hub bearings are closer. This causes them to loosen up much more frequently than the earlier hubs.

2) Halfshafts are much smaller at the CV joint making the shaft and CV joint much weaker.

3) The wider radius arms flex much less than the narrow radius arms.

MountainD

Technical Excellence Contributor

The later 24 spline axles are weaker than the early 10 spline axles.

1) Hub bearings are closer. This causes them to loosen up much more frequently than the earlier hubs.

2) Halfshafts are much smaller at the CV joint making the shaft and CV joint much weaker.

3) The wider radius arms flex much less than the narrow radius arms.

Got you. I knew about the CV being stronger, but I am pretty sure the axles are weaker--regardless on that, I have GBR CV's already that will be going back in. I thought that the less flex issue on the wider radius arms was a good thing... I'll look into what you are saying but don't want to overtake his thread. Thanks for the info--it is appreciated.

Edit: and for posterity, I did see that Ashcroft did run some tests and the 10 spline were stronger in front than the 24 spline (but weaker in rear) so your point is well taken.

Last edited:

Got you. I knew about the CV being stronger, but I am pretty sure the axles are weaker--regardless on that, I have GBR CV's already that will be going back in. I thought that the less flex issue on the wider radius arms was a good thing... I'll look into what you are saying but don't want to overtake his thread. Thanks for the info--it is appreciated.

The stock halfshafts are 32 spline at the CV on the later axles and 23 spline on the earlier.

Less flex is bad for off road. I assume you are using it off road or there would be no point to making the axles stronger.

Tbaumer

Technical Excellence Contributor

Glad you told me that because that's what I was about to do. I'm putting my drain plugs back in & topping with gear oil to the fill plug, so I can get back to driving until I'm ready to put new seals in - THEN it's decision time.Btw: don't use synthetic 90wt. It leaks quicker than normal stuff.

Really enjoyed this thread. I'd like to revive it in order to ask a couple questions about running "wet" hubs...

I recently stripped down my swivels and steering knuckles in order to change my swivel seals, and after reading this thread I am now considering running "wet" hubs. My vehicle is a 1998 Discovery 1. So, my questions are:

1.) If I remove the swivel ball half shaft seal (FTC3276G) from the inner swivel ball, 75w90 gear oil will be permitted to migrate from the differential into the swivel ball, and further to the wheel bearings, correct?

2.) If the wheel bearings are coated in gear oil, presumably the only seals retaining the gear oil are the hub seal and the inner rotor seal (inner wheel bearing seal), correct? If so, are the tolerances tight enough to where the inner wheel bearing seal will keep the gear oil from leaking through it?

3.) I neither have leveling nor drain ports on the front of my steering knuckles. I only have a port for adding one-shot grease. Without the drain ports, is it really smart to run gear oil in the swivels? To drain the oil every 25k, should I just take off the hubs and let the oil drain out? Or?

Thanks!

I recently stripped down my swivels and steering knuckles in order to change my swivel seals, and after reading this thread I am now considering running "wet" hubs. My vehicle is a 1998 Discovery 1. So, my questions are:

1.) If I remove the swivel ball half shaft seal (FTC3276G) from the inner swivel ball, 75w90 gear oil will be permitted to migrate from the differential into the swivel ball, and further to the wheel bearings, correct?

2.) If the wheel bearings are coated in gear oil, presumably the only seals retaining the gear oil are the hub seal and the inner rotor seal (inner wheel bearing seal), correct? If so, are the tolerances tight enough to where the inner wheel bearing seal will keep the gear oil from leaking through it?

3.) I neither have leveling nor drain ports on the front of my steering knuckles. I only have a port for adding one-shot grease. Without the drain ports, is it really smart to run gear oil in the swivels? To drain the oil every 25k, should I just take off the hubs and let the oil drain out? Or?

Thanks!

erover82

Well-known member

Really enjoyed this thread. I'd like to revive it in order to ask a couple questions about running "wet" hubs...

I recently stripped down my swivels and steering knuckles in order to change my swivel seals, and after reading this thread I am now considering running "wet" hubs. My vehicle is a 1998 Discovery 1. So, my questions are:

1.) If I remove the swivel ball half shaft seal (FTC3276G) from the inner swivel ball, 75w90 gear oil will be permitted to migrate from the differential into the swivel ball, and further to the wheel bearings, correct?

2.) If the wheel bearings are coated in gear oil, presumably the only seals retaining the gear oil are the hub seal and the inner rotor seal (inner wheel bearing seal), correct? If so, are the tolerances tight enough to where the inner wheel bearing seal will keep the gear oil from leaking through it?

3.) I neither have leveling nor drain ports on the front of my steering knuckles. I only have a port for adding one-shot grease. Without the drain ports, is it really smart to run gear oil in the swivels? To drain the oil every 25k, should I just take off the hubs and let the oil drain out? Or?

Thanks!

1.) Oil will migrate into the swivel housing, but not the hub because there is a seal in the stub axle beneath the CV thrust bearing.

2.) Oil cannot reach the wheel bearings because of aforementioned seal.

3.) I’d just pull the stub axle at that interval. It’s not difficult and gives you a chance to inspect everything and grease the wheel bearings.

I like the one shot because it’s easy, leaks less, and makes inner seal failure more visible. Gear oil works perfectly fine too.

Last edited:

Wet hubs are great till they aren’t. Others here may disagree but personally, I would run them as the factory engineers designed them, sealed and greased.

I forgot all about the seal in the stub axle. Thanks for the reminder, as well as the clarification. I already have everything apart in order to reseal the entire system (as well as repack the wheel bearings), so now its decision time : )1.) Oil will migrate into the swivel housing, but not the hub because there is a seal in the stub axle beneath the CV thrust bearing.

2.) Oil cannot reach the wheel bearings because of aforementioned seal.

3.) I’d just pull the stub axle at that interval. It’s not difficult and gives you a chance to inspect everything and grease the wheel bearings.

I like the one shot because it’s easy, leaks less, and makes inner seal failure more visible. Gear oil works perfectly fine too.