You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

GM/Chevy 250 Conversion in 90/110/130

- Thread starter RDavisinVA

- Start date

RDavisinVA

Technical Excellence Contributor

pics people !

Don't understand your post. If you were asking for pictures, were all the extensive pictures in posts 82, 83, 85, and 87 not enough for you???

New tank for the 250 .. Had some left over raptor liner so I roughed up the tank and primed and coated it ... new fittings for the fuel lines I need to run also attached

More pictures for Matt in post 101, if he was asking for them.

Brian, looks like the right side of the fuel tank got banged up pretty good.

You show 3 fuel connections on the talk, not counting the air vent, sender, top, and right rear, but you need a feed and a return.

Which 2 are you intending to use?

looks great. I ran a ground to the stud for the sender to the fram eon my early tank like that after getting intermittent gauge performance

Great advice as the sender needs a (-) ground wire to read true.

Last edited:

Put the timing cover and oil pan back on (man I hope this doesn’t leak)

I was going to give the crank pulley another go now that I have drillled and tap the crank. when I inspected it I noticed this.

No doubt I caused this and that the key in fact did ride up and cracked the pulley.

I will be taking this back to Napa tomorrow and hopefully they will exchange or I will have to chalk it up to learning experience.

I was going to give the crank pulley another go now that I have drillled and tap the crank. when I inspected it I noticed this.

No doubt I caused this and that the key in fact did ride up and cracked the pulley.

I will be taking this back to Napa tomorrow and hopefully they will exchange or I will have to chalk it up to learning experience.

RDavisinVA

Technical Excellence Contributor

It happens.

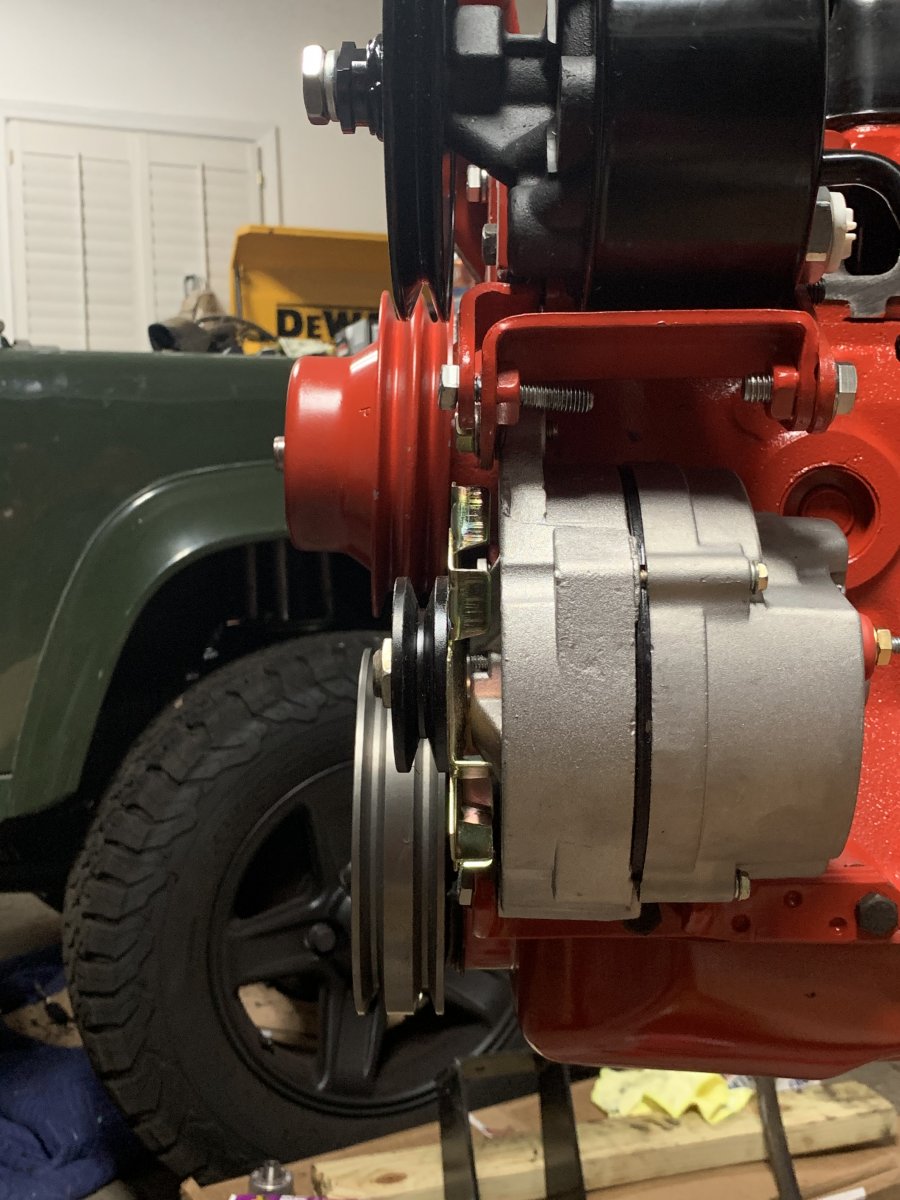

Replacement part came in ... 30 mins later it was on ... went on and felt it seat against crank shaft ... looks to be lined up perfectly with water pump pulley grooves. Ordered a crank shaft bolt to make sure this sucker doesn’t go anywhere ... the key stayed and place and can been seen from the front.

Highly recommend drilling and tapping the crank as is said in Roberts instructions ...

Highly recommend drilling and tapping the crank as is said in Roberts instructions ...

It’s funny you say that I am mocking everything up now to make sure it all is going to work before I drop it in the defender

all the grooves on the inner groves line up as you can see here with the old belt.

however the groves on the crank shaft pulley and water pump pulley do not line up on the groves closest to camera.

I am guessing if I switch the power steering pulley for a double grove it might line up with free Water pump pulley Groove.

so belt one would go crank shaft to water pump to alternator

and belt two would be water pump to Power steering.

I may be totally missing something here.

The crank shaft pulley has a much larger section between groove than the water pump pulley

Robert any suggestions here ... your kit arrived today so I am getting closer !

all the grooves on the inner groves line up as you can see here with the old belt.

however the groves on the crank shaft pulley and water pump pulley do not line up on the groves closest to camera.

I am guessing if I switch the power steering pulley for a double grove it might line up with free Water pump pulley Groove.

so belt one would go crank shaft to water pump to alternator

and belt two would be water pump to Power steering.

I may be totally missing something here.

The crank shaft pulley has a much larger section between groove than the water pump pulley

Robert any suggestions here ... your kit arrived today so I am getting closer !

Last edited:

Napalm00

Technical Excellence Contributor

I feel like then you're running technically The alternator and the water pump and the power steering off of a single belt. since you only have one belt that connects to the crank all of the power is being transmitted through that belt.

Robert probably has the answer here but I'm thinking instead of putting a double pulley on the power steering pump, you should move the alternator forward so that the alternator and the crank has its own belt on the front of the crank.

Leave the power steering pump where it is and run power steering water pump and crank.

This way you aren't transmitting all of this power through a single belt each one of the items that is actually going to draw power has its own belt.

Robert probably has the answer here but I'm thinking instead of putting a double pulley on the power steering pump, you should move the alternator forward so that the alternator and the crank has its own belt on the front of the crank.

Leave the power steering pump where it is and run power steering water pump and crank.

This way you aren't transmitting all of this power through a single belt each one of the items that is actually going to draw power has its own belt.

looking of past post here is image of Roberts set up RHD no ac

looks like my crank pulley is different than his

Last edited:

acheck

Well-known member

A friend of mine who's not on the forum is asking me about these conversions.

Is the kit fully inclusive of all parts? If not, is there a definitive parts list so everything can be easily sourced?

Also, how complete are the instructions?

Would like to hear from some of you who have actually done this in your own garages.

Thanks

Is the kit fully inclusive of all parts? If not, is there a definitive parts list so everything can be easily sourced?

Also, how complete are the instructions?

Would like to hear from some of you who have actually done this in your own garages.

Thanks

RDavisinVA

Technical Excellence Contributor

Hey guys. Don't confuse these DIY owners doing conversions with incorrect advice.

When GM built the Chevy 6 cylinders, they manufactured different ancillary pulley systems with different spacing for different applications that included, alternator, power steering, air conditioning, smog air injection pumps, hydraulic pumps, and governors.

These engines were manufactured until around 2010 in Mexico and South America, some say later, but this is unconfirmed and based on what some self proclaimed experts have told me so don't think it matters herein, but thought I would mention it for all the haters that keep calling the engine ancient as they poke fun at a conversion that is rapidly gaining ground for obvious reasons.

For the typical automotive use, the engines had 2 types of pulley spacings:

1.) Pulleys with grooves spaced apart

The grooves were spaced apart to prevent the V-belts from rubbing against one another when driving 2 or more ancillary devices located on the same side of the engine.

If the belt grooves were not spaced apart, there is risk that the belts could rub one another when slightly loose, wear the sides out and fail.

To prevent this from happening GM developed ancillary pulley systems with the V-belt grooves spaced apart so the belts cannot rub.

2.) Pulleys with grooves spaced next to each other (spaced together)

The pulleys with the V-belt grooves spaced together were used in several different applications, but typically had the ancillaries on opposite sides of the engine where the belts would never run the risk of rubbing.

The other use for these pulleys was when only 1 ancillary was driven, usually an alternator on the left side.

I won't go into the different AC compressors and hydraulic pumps and so on, but will mention that I have manufactured ancillary mounts that will fit the alternator, Sanden AC Compressor, and Saginaw Power Steering Pump.

Guys who like to advise others, please do it with caution and not shoot from the dark when it comes to the 250 conversions.

Brian has RHD with power steering without AC.

He has the wrong water pump pulley with the power steering for a GMC truck that uses the first pulley instead of the second.

In over 20 installs, I have helped coach, he is the second person to experience this.

Everyone else with RHD was able to use the factory power steering and alternator mounts and drop their engine in and use them.

Am going to offer to trade a set of Chevy power brackets that will line up with the second belt and a water pump pulley to match his crank pulley.

Then he can continue with his bolt in, bolt-up conversion.

So please don't tell Brian to buy a different crank pulley as that advice is incorrect.

When GM built the Chevy 6 cylinders, they manufactured different ancillary pulley systems with different spacing for different applications that included, alternator, power steering, air conditioning, smog air injection pumps, hydraulic pumps, and governors.

These engines were manufactured until around 2010 in Mexico and South America, some say later, but this is unconfirmed and based on what some self proclaimed experts have told me so don't think it matters herein, but thought I would mention it for all the haters that keep calling the engine ancient as they poke fun at a conversion that is rapidly gaining ground for obvious reasons.

For the typical automotive use, the engines had 2 types of pulley spacings:

1.) Pulleys with grooves spaced apart

The grooves were spaced apart to prevent the V-belts from rubbing against one another when driving 2 or more ancillary devices located on the same side of the engine.

If the belt grooves were not spaced apart, there is risk that the belts could rub one another when slightly loose, wear the sides out and fail.

To prevent this from happening GM developed ancillary pulley systems with the V-belt grooves spaced apart so the belts cannot rub.

2.) Pulleys with grooves spaced next to each other (spaced together)

The pulleys with the V-belt grooves spaced together were used in several different applications, but typically had the ancillaries on opposite sides of the engine where the belts would never run the risk of rubbing.

The other use for these pulleys was when only 1 ancillary was driven, usually an alternator on the left side.

I won't go into the different AC compressors and hydraulic pumps and so on, but will mention that I have manufactured ancillary mounts that will fit the alternator, Sanden AC Compressor, and Saginaw Power Steering Pump.

Guys who like to advise others, please do it with caution and not shoot from the dark when it comes to the 250 conversions.

Brian has RHD with power steering without AC.

He has the wrong water pump pulley with the power steering for a GMC truck that uses the first pulley instead of the second.

In over 20 installs, I have helped coach, he is the second person to experience this.

Everyone else with RHD was able to use the factory power steering and alternator mounts and drop their engine in and use them.

Am going to offer to trade a set of Chevy power brackets that will line up with the second belt and a water pump pulley to match his crank pulley.

Then he can continue with his bolt in, bolt-up conversion.

So please don't tell Brian to buy a different crank pulley as that advice is incorrect.