WreckITFrank

Technical Excellence Contributor

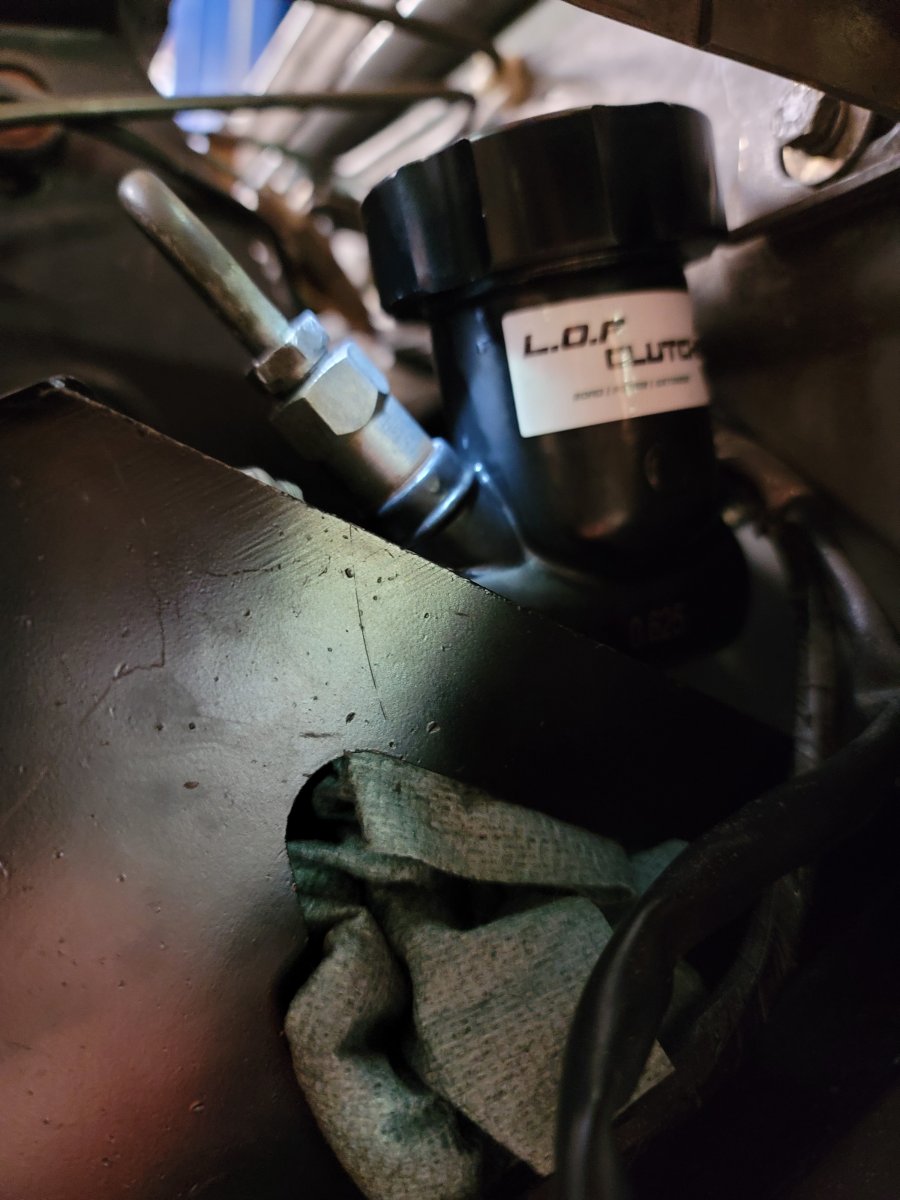

Spent a few hours swapping a td5 pedal box. Seems pretty straightforward yet getting my ass kicked.

Lof master and spring. Td5 pedal box, as far as I know. Bled for a while and getting a firm while at bottom of engagement. But the rod in the master is hitting the rear wall of the box. Could the throw of the master be too long? The 5.5" measurement, I can't seem to achieve that, should it be done without the spring? The newer style box the spring hold the pedal way the way up, out all the way down. We pulled the slave and it's pressed out, and the rod seems lose on the fork but still attached.

The best I had so far was if I pulled the pedal up, it would quickly spring against the bulkhead. If I fully push it, it will lock down. If pump by hand, the lower end of depress had a little resistance. Not sure how the pedal stop works, as it doesn't push the pedal off the floor enough to really stop anything.

Open to any suggestions. Thanks

Lof master and spring. Td5 pedal box, as far as I know. Bled for a while and getting a firm while at bottom of engagement. But the rod in the master is hitting the rear wall of the box. Could the throw of the master be too long? The 5.5" measurement, I can't seem to achieve that, should it be done without the spring? The newer style box the spring hold the pedal way the way up, out all the way down. We pulled the slave and it's pressed out, and the rod seems lose on the fork but still attached.

The best I had so far was if I pulled the pedal up, it would quickly spring against the bulkhead. If I fully push it, it will lock down. If pump by hand, the lower end of depress had a little resistance. Not sure how the pedal stop works, as it doesn't push the pedal off the floor enough to really stop anything.

Open to any suggestions. Thanks