Tbaumer

Technical Excellence Contributor

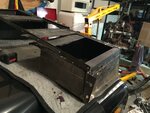

I'm 6'3", so I added MudUK seat rails to increase my leg room. They are an improvement, but raised my sitting height almost 2". Now I duck a little to see lights at intersections & even more to see out my side windows. It'd be simple to fabricate a seat box that allows the use of extenders & have the seats at the original height. I can alter (or keep) the original seat box or bend a 16 gauge galvanized sheet metal seat box. As long as I allow room for the tunnel (The middle can stay raised - make the cubby more of an arm rest), is there any reason I shouldn't alter the design?

Has anybody done this? Any advise or ideas?

Has anybody done this? Any advise or ideas?